Alright, on that car, ground up, here we go. You will need a 12mm end wrench, 14mm end wrench, a small sledge hammer (something like 4lbs is good), an impact screwdriver (Auto Zone sells them as I mentioned), a jack (and then use your car jack from the trunk as a safety jack), a small flat chisel/punch or a couple of small flat blade screwdrivers, 1/2 inch drive breaker bar, 24 or 22mm socket (honda lists both, so I cant tell if they used both sizes or what), and of course your new bearing.

1) Break the lug nuts loose while the car is on the ground

2) jack up the car until the tire is off the ground and secure it with a safety jack. You want to be lifting the car by the pinchweld which looks esactly like it sounds- the long seam running front to back, there are even arrows pointing to it molded into the plastic rocker panels.

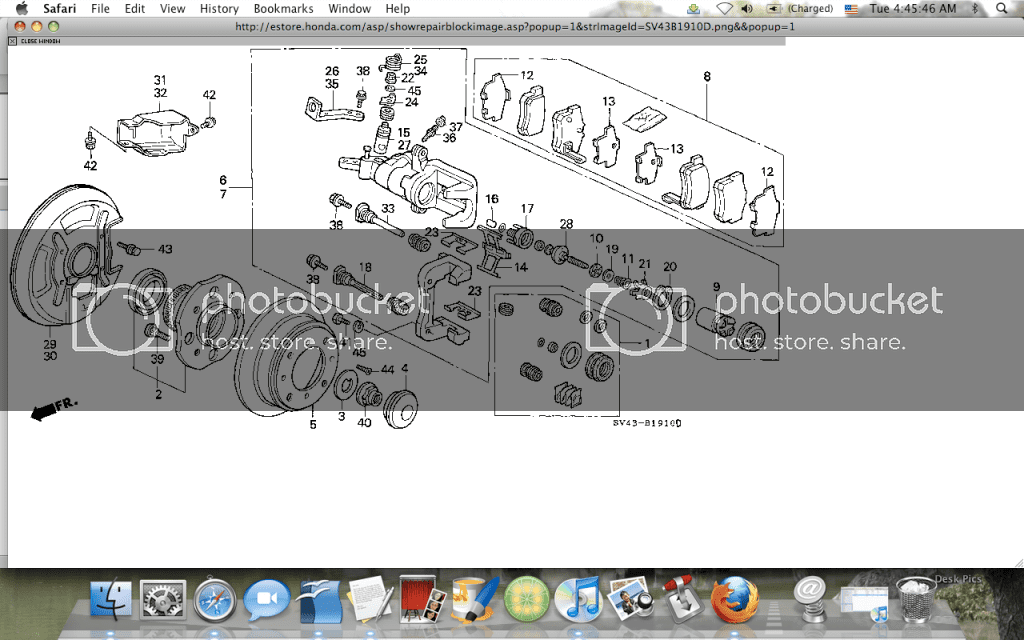

3) finish loosening the lug nuts and remove the rear wheel. Next, take the two 12mm bolts out of the brake caliper. Lay the caliper aside.

4) Remove the 2 caliper bracket bolts using a 14mm wrench. By the way, you can tap a wrench with the hammer to break bolts loose, it generally wont hurt the wrench, just be damn sure you're turning counterclockwise to loosen.

5) Take the impact screwdriver and make sure its in reverse. Set it into the two phillips screws in the brake rotor and tap with a hammer- by tap I mean hit really effing hard. If you get the two screws out without stripping them, slide the brake rotor off and lay it aside. If you strip the screw heads or break off the tip of your phillips bit, you will learn a new skill called drilling hardened metal. Use a drill with a half inch or so bit and drill the head of the bolt out. Its a pain but I've done it a lot and it can be done.

6) Use a chisel and the hammer to pry back that gold cap in the center of the bearing. Wood chisels work best for this.

7) Now you can see the giant 22mm or 24mm nut that is "staked" or has been hammered in in one place to secure it. As I stated, use the hammer and a chisel or small screwdriver to unstake it-you're trying to make it round again. Once you do this, but the huge breaker bar and socket on there and wrench it off. Now you can slide the bearing/hub assembly straight out.

8) slide the new bearing on, and make sure you put the washer on before reinstalling the nut.

9) Putting it back together is the reverse of this. Tips for reassembly-

10) Use sil glide or synthetic grease to lubricate all nuts and bolts- if you have to work on it in the future this prevents things from rusting and being an overall pain in the dick later. Particularly grease those little screws that hold the rotor on- and dont tighten them very tight, just get them as tight as you can with a regular phillips screwdriver, don't use the impact to put them on.

11) Pull the slide pins out of the brake caliper bracket (the part the pads rest in) and wipe off the old grease, replacing it with new grease. Don't use too much or or you will again have a problem, but it is critical you check on your brakes while you're in there. If they won't move in our out (it's the parts with the rubber boot around them that the caliper bolts onto) the you will have to force them out. Get a bore cleaner brush if they are seized so you can clean the holes out once you get the pins out. Use sandpaper to buff the old pins up until they shine.

12) If your brake pads or rotor look shot, replace them.

13) Don't over tighten the nut, just put it back on in the position that it was.

That's the simple version, if it gets terribly tricky post any questions and I'll try to respond.