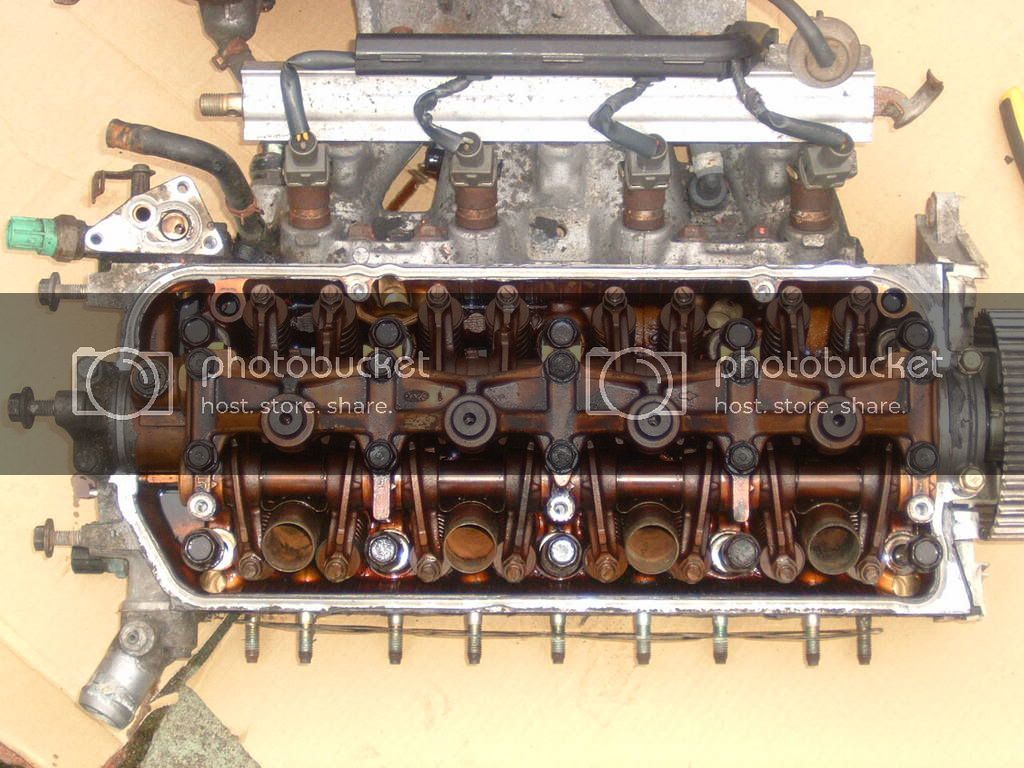

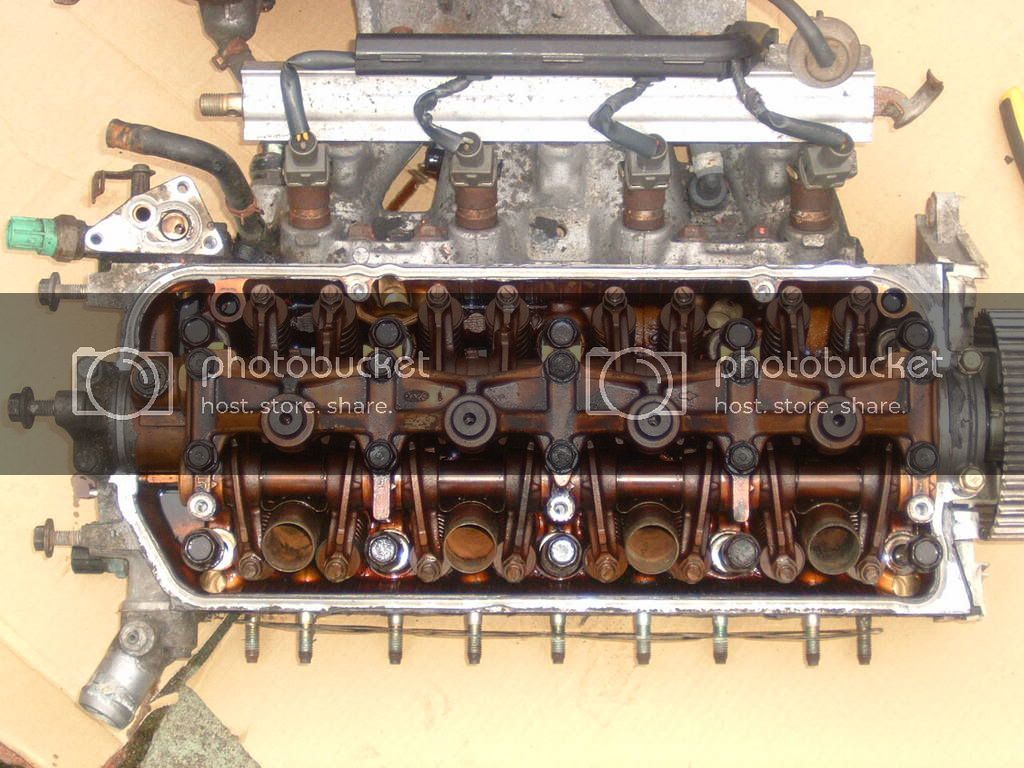

Hi, i've finally decided to rebuild my old z6 for turbo. Not looking for crazy number ( arround 225-250 hp).

1- I wanted to know based on the pics if i'm wasting my time. The engine has 154000 miles ( i know it doesn't matter if your going to re build it) but what you guys think?

2- Also what type , brand of internal would you go with ( will be using the greddy bolt-on kit TD04H-15G 8cm2 ). I know that with that kit i can keep the stock internal, but in case later i want more power i don't want to have to open the block again. Any suggestion on setup will be great .

Does anyone know a machine shop in the boston Massachusetts area where i can send my block and head to be cleaned , resurfaced, bored , honed and a valve job ? If not any trusted shop will be great Thanks.

1- I wanted to know based on the pics if i'm wasting my time. The engine has 154000 miles ( i know it doesn't matter if your going to re build it) but what you guys think?

2- Also what type , brand of internal would you go with ( will be using the greddy bolt-on kit TD04H-15G 8cm2 ). I know that with that kit i can keep the stock internal, but in case later i want more power i don't want to have to open the block again. Any suggestion on setup will be great .

Does anyone know a machine shop in the boston Massachusetts area where i can send my block and head to be cleaned , resurfaced, bored , honed and a valve job ? If not any trusted shop will be great Thanks.

Last edited: