hatukazi

ambitious...but rubbish

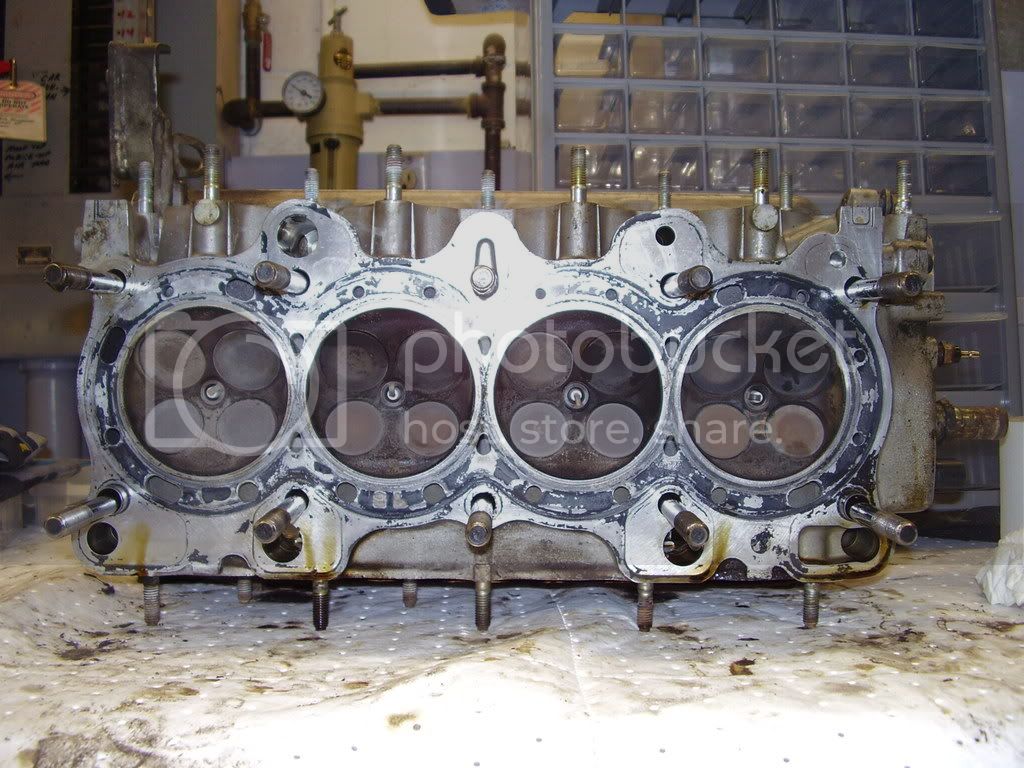

well I am taking the plunge and rebuilding my B16, I have a few questions.

this is a class project and we have to strip it down completely, all machine work is free so that's a bonus.

so that's a bonus.

question 1,

I have to strip my head for a valve job and I am worried about the lost motion assemblies, how to remove them for the jet-wash and not to get shavings in them from the valve seat machine.

question 2,

I will need a set of valves, king motorsports (I cant link to them specifically) has buddy club valves a whole set for $300, good deal? or can I do better?

question 3,

bearings, the block will be line honed so i will need new bearings, I want really good ones and this will be a daily driver so not a race set up, any suggestions?

question 4,

I am hoping to be able to re-use my stock pistons, but I will definatly need new rings, I was thinking total seal gapless, worth it?

#5,

Spoon Sports

worth $140?

#6,

are e-bay gasket kits a waste of money?, I know I dont want to use the head gasket that comes with them, but for like the oil pan and valve cover and o-rings and stuff I thought might be OK.

right now I am trying to get a bare bones estimate of how much I will need, I dont want to skimp, I want honda reliability this time (9 hondas and one has been reliable) but this time if it messes up it will be on me.

I will also be taking pictures and posting progress.

comments welcome and advice appreciated, wish me luck!

this is a class project and we have to strip it down completely, all machine work is free

question 1,

I have to strip my head for a valve job and I am worried about the lost motion assemblies, how to remove them for the jet-wash and not to get shavings in them from the valve seat machine.

question 2,

I will need a set of valves, king motorsports (I cant link to them specifically) has buddy club valves a whole set for $300, good deal? or can I do better?

question 3,

bearings, the block will be line honed so i will need new bearings, I want really good ones and this will be a daily driver so not a race set up, any suggestions?

question 4,

I am hoping to be able to re-use my stock pistons, but I will definatly need new rings, I was thinking total seal gapless, worth it?

#5,

Spoon Sports

worth $140?

#6,

are e-bay gasket kits a waste of money?, I know I dont want to use the head gasket that comes with them, but for like the oil pan and valve cover and o-rings and stuff I thought might be OK.

right now I am trying to get a bare bones estimate of how much I will need, I dont want to skimp, I want honda reliability this time (9 hondas and one has been reliable) but this time if it messes up it will be on me.

I will also be taking pictures and posting progress.

comments welcome and advice appreciated, wish me luck!