You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boost & HP Level

- Thread starter Turbo&Auto

- Start date

- Replies 56

- Views 7K

We may earn a small commission from affiliate links and paid advertisements. Terms

Turbo&Auto

Nick Go FAST!!

He claims he has a degree in Fluid Dynamics  Degree or not, he's WAY off.

Degree or not, he's WAY off.

This is his last post:

Ok man,

cfm is a FLOW measurement, NOT a PRESSURE measurement. Don't mix em up. And psi is not just a number. Its POUNDS PER SQUARE INCH. If you have a volume (your intake manifold) and you have 5 psi of air in there, it's the same 5 psi regardless of the size of turbo. If you have a large turbo at 5 psi boost, the flow THROUGH the INTAKE MANIFOLD will be the same as the flow THROUGH the INTAKE MANINFOLD at 5 psi boost from a small turbo.

Here is the diff two turbos, same boost pressure, assuming same size intake piping intercooler and throttle body and intake manifold;

Large turbo: doesn't have to spool as fast as the smaller turbo, larger compressor housing, less velocity, same volume, as soon as the air exits the turbo and enters the rest of the intake piping and intake manifold same flow!

Small turbo: has to spool faster, smaller compressor housing, same volume through smaller compressor = more velocity, as soon as air enters same intake tract as large turbo, SAME FLOW!!!

Dude, what i'm saying is you WILL get the SAME POWER at the SAME BOOST LEVEL with any turbo.

Lets say 10psi makes 250whp on whatever car with a smaller turbo. If you install a larger turbo and run 10psi, it will still make 250whp, just at a different rpm.

Think about it man!

I came back with this:

LHO, So why are there all of these compressor maps and different sized turbos man? They all make the same power why have choices?

PLEASE sit back and think about what you're saying because its way off. If you want to make drag comparisons, Wish100K was running a T25 at 8psi, it took him like 17 seconds to get to 100. Then he switched out to a Big16G equivelent, it only took 12-13 seconds to get to 100 at the same boost level. Cant be possible right, same boost level, same HP

I think not man. I'm sorry but you're wrong here.

I think not man. I'm sorry but you're wrong here.

Edit:

you said 5psi in the intake manfiold is 5psi, thats true, but the volume is NOT the same.

Take a 2 liter Pepsi bottle and pressure it to 5psi, then do the same with a spackle bucket. You're saying the Pepsi bottle has the same volume as the spackle bucket? NO FRIGGIN WAY! MORE AIR = MORE POWER!!!

This is his last post:

Ok man,

cfm is a FLOW measurement, NOT a PRESSURE measurement. Don't mix em up. And psi is not just a number. Its POUNDS PER SQUARE INCH. If you have a volume (your intake manifold) and you have 5 psi of air in there, it's the same 5 psi regardless of the size of turbo. If you have a large turbo at 5 psi boost, the flow THROUGH the INTAKE MANIFOLD will be the same as the flow THROUGH the INTAKE MANINFOLD at 5 psi boost from a small turbo.

Here is the diff two turbos, same boost pressure, assuming same size intake piping intercooler and throttle body and intake manifold;

Large turbo: doesn't have to spool as fast as the smaller turbo, larger compressor housing, less velocity, same volume, as soon as the air exits the turbo and enters the rest of the intake piping and intake manifold same flow!

Small turbo: has to spool faster, smaller compressor housing, same volume through smaller compressor = more velocity, as soon as air enters same intake tract as large turbo, SAME FLOW!!!

Dude, what i'm saying is you WILL get the SAME POWER at the SAME BOOST LEVEL with any turbo.

Lets say 10psi makes 250whp on whatever car with a smaller turbo. If you install a larger turbo and run 10psi, it will still make 250whp, just at a different rpm.

Think about it man!

I came back with this:

LHO, So why are there all of these compressor maps and different sized turbos man? They all make the same power why have choices?

PLEASE sit back and think about what you're saying because its way off. If you want to make drag comparisons, Wish100K was running a T25 at 8psi, it took him like 17 seconds to get to 100. Then he switched out to a Big16G equivelent, it only took 12-13 seconds to get to 100 at the same boost level. Cant be possible right, same boost level, same HP

Edit:

you said 5psi in the intake manfiold is 5psi, thats true, but the volume is NOT the same.

Take a 2 liter Pepsi bottle and pressure it to 5psi, then do the same with a spackle bucket. You're saying the Pepsi bottle has the same volume as the spackle bucket? NO FRIGGIN WAY! MORE AIR = MORE POWER!!!

Last edited:

Turbo&Auto

Nick Go FAST!!

Thanks B, I knew thats what I would hear. He's starting to see the light now, I think the pepsi bottle BS story I made helped get the point across.

Actually... both of you are right, both of you are wrong, and both of you are missing the point. Seriously.

Turbo&Auto

Nick Go FAST!!

enlighten me then

It's going to take about an hour of typing...

I do.

Ooooooooooooook. This is why you're both right and wrong, and both totally missing the point.

1. LHO is correct in saying that psi is psi no matter what turbo it comes from. Pressure is pressure. It is measured at the intake manifold, so if your boost gauge shows 4psi, you have 4psi. It's that simple. He is also correct in saying that the bigger turbo just applies that 4psi later in the rev range of the engine.

2. He is NOT correct in saying that the bigger turbo will make the same amount of power at the same pressure level as the smaller turbo- not unless both are pushing the same pressure at the same engine RPM, and at the same efficiency.

3. LHO's post about volume vs flow rate vs fixed volume of the intake manifold is correct. Pressure is pressure. 5psi on a manifold is going to flow the same amount at the same engine RPM no matter what turbo is pushing it.

4. T&A is correct in saying that 300cfm will make more power than 200cfm provided you have the fuel to use it- but only partially correct.

5. LHO's comeback saying that 10psi will make 250whp (arbitrary example) no matter which turbo its from is incorrect. He's leaving something out.

6. T&A's last comeback talking about different compressor maps is starting to show some understanding about the whole debate.... but doesn't lay it all out there.

Alrighty T&A (and LHO), let's all go to school.

----- I know a lot of you know a lot of this stuff already, but just sit tight. -----

Engines are big energy converters / reactors. They convert the latent energy contained in fuel to thermal energy that pushes pistons/rotors around, which act on lever arms (rods, crankshaft) to create torque. Power is a function of that torque applied over time. The faster you apply the torque (higher rpm), the more power you get- even if you have the same amount of torque.

Higher amounts of fuel and air mean more energy is released in the reaction (combustion), so you get more torque and therefore more power.

Now air on its own isn't the important part. Oxygen is- that's what reacts with the fuel to make a nice boom and push your pistons around. Density is the key. With turbochargers, when you look at a compressor map, you see all those wonderful efficiency islands. Higher efficiency values mean higher air densities- and therefore higher oxygen densities.

Take an imaginary box. When it's full, this imaginary box holds one pound of air. Now let's squish that air to half its size- the equivalent of 14.7psi (1 atm) of boost. Squish more air the same amount and fill the box to the top. At 100% efficiency (not possible, but imagine), you'll have exactly two pounds of air in the box. Twice the air means twice the potential to burn more fuel, right? With 2 pounds of air in the box (or engine) that's designed to hold only 1 pound, you have the opportunity to burn twice as much fuel and make twice as much torque.

Let's say your turbo is only operating at 80% efficiency. At 1atm (14.7psi) of boost, you'll spend 20% of your turbo's work generating heat, and only 80% of the work will go to compressing air. The air heats up, and you have only 1.6 pounds that are usable to potentially burn fuel, not 2 pounds like you had before. The box is still full to the top. You have the same pressure, the same volume (so the same FLOW), but less oxygen available to burn fuel.

All of this assumes you have a box with no hole in it.

Your engine is this box with a hole in it. Well, I guess your intake manifold is, but you get the idea. The faster your engine is turning, the bigger the hole gets. This is where flow rate comes into play. The faster your engine runs, the more flow the turbo has to provide to establish the same pressure ratio. That's why small turbos run out up top- because they can't move enough air to maintain pressure against the engine once the engine is gobbling up more air.

Addressing points:

1. Yes, pressure is pressure- but assuming everything else is the same. LHO has to assume that both setups have engines of the exact same displacement running at the same speed. With a 2 liter engine running at a constant 4000rpm, a turbo pushing 4psi against it is always pushing the same volume of air, no matter what the turbo size. Pressure is pressure.

2. On the bigger turbo making the same amount of power but just at a different RPM, that makes no sense. LHO is already stating that the larger turbo will make boost at a higher engine speed than the smaller turbo, and that's correct. Everyone knows that. Assuming the same efficiency, a small turbo pushing 10psi at 5000rpm will make half as much power as a turbo pushing 10psi at 10000rpm. Both engine setups are making the same amount of torque- they're both burning the same amount of fuel per engine revolution- but since the 10000rpm engine is applying that force twice as fast as the 5000rpm engine, it makes twice as much power. Easy. So... if the larger turbo is making the same pressure as the smaller turbo but does it higher up in the rev range of the engine, then it will make more power at the same pressure level, not the same amount of power. That's just a function of engine speed.

I'm sure homie LHO would come back with something like "oh, the small turbo can make 10psi in the same place that the big turbo can," and he might be right- but then this is where all the efficiency fun comes into play. The small turbo might be able to push 10psi at 10k just like the bigger turbo, but it won't do it as efficiently as the larger turbo. Even at the same flow rate and the same pressure, the larger turbo will flow more MASS into the engine because it is operating more efficiently. The small turbo is just generating heat because it's out of range, while the larger turbo is working pushing more air. Same pressure, same CFMs, different mass flow rate, different power outputs.

3. See #1. 5psi is 5psi, assuming the engine is consuming air at the same speed in both cases (box with hole in it). You have a constant cross section for air to flow across, you have the same pressure differential, and you have the same amount of air going out. Everything is identical.

4. Yes, more flow = more power... generally. When you're reading the compressor maps for a turbocharger, they're mapped with pressure ratio vs flow rate. Just because a turbo can flow a certain amount of air volume doesn't mean that it can succesfully push that volume into an engine at a certain pressure. You could theoretically have a turbo that could push 500cfm, but only be capable of pushing it at 1psi. Any more resistance, and you don't get that flow rate. The turbo must have both the capability to flow the volume AND be able to maintain pressure to push it into an engine.

Also, talking about flow on its own without reference to the density of that flow is misleading. Flow on its own doesn't tell you anything. You can flow the same volume of light sugar water and thick molasses- and they will be the same flow rate- but you get totally different amounts of sweetness, right? I generally think that people who just talk "oh but this one FLOWS more CFMs" without mentioning efficiencies or air densities doesn't fully understand what they're talking about.

5. See efficiency.

6. Yay T&A! Talking about compressor maps... but it's not just the volume vs pressure that are important- the efficiency islands are the most important part of the compressor map.

-----

So basically- T&A is a lot more right than LHO, but LHO is technically right in most of his stuff. He just doesn't have the whole picture.

I hope that clears things for some people and doesn't muddy the waters for too many....

1. LHO is correct in saying that psi is psi no matter what turbo it comes from. Pressure is pressure. It is measured at the intake manifold, so if your boost gauge shows 4psi, you have 4psi. It's that simple. He is also correct in saying that the bigger turbo just applies that 4psi later in the rev range of the engine.

2. He is NOT correct in saying that the bigger turbo will make the same amount of power at the same pressure level as the smaller turbo- not unless both are pushing the same pressure at the same engine RPM, and at the same efficiency.

3. LHO's post about volume vs flow rate vs fixed volume of the intake manifold is correct. Pressure is pressure. 5psi on a manifold is going to flow the same amount at the same engine RPM no matter what turbo is pushing it.

4. T&A is correct in saying that 300cfm will make more power than 200cfm provided you have the fuel to use it- but only partially correct.

5. LHO's comeback saying that 10psi will make 250whp (arbitrary example) no matter which turbo its from is incorrect. He's leaving something out.

6. T&A's last comeback talking about different compressor maps is starting to show some understanding about the whole debate.... but doesn't lay it all out there.

Alrighty T&A (and LHO), let's all go to school.

----- I know a lot of you know a lot of this stuff already, but just sit tight. -----

Engines are big energy converters / reactors. They convert the latent energy contained in fuel to thermal energy that pushes pistons/rotors around, which act on lever arms (rods, crankshaft) to create torque. Power is a function of that torque applied over time. The faster you apply the torque (higher rpm), the more power you get- even if you have the same amount of torque.

Higher amounts of fuel and air mean more energy is released in the reaction (combustion), so you get more torque and therefore more power.

Now air on its own isn't the important part. Oxygen is- that's what reacts with the fuel to make a nice boom and push your pistons around. Density is the key. With turbochargers, when you look at a compressor map, you see all those wonderful efficiency islands. Higher efficiency values mean higher air densities- and therefore higher oxygen densities.

Take an imaginary box. When it's full, this imaginary box holds one pound of air. Now let's squish that air to half its size- the equivalent of 14.7psi (1 atm) of boost. Squish more air the same amount and fill the box to the top. At 100% efficiency (not possible, but imagine), you'll have exactly two pounds of air in the box. Twice the air means twice the potential to burn more fuel, right? With 2 pounds of air in the box (or engine) that's designed to hold only 1 pound, you have the opportunity to burn twice as much fuel and make twice as much torque.

Let's say your turbo is only operating at 80% efficiency. At 1atm (14.7psi) of boost, you'll spend 20% of your turbo's work generating heat, and only 80% of the work will go to compressing air. The air heats up, and you have only 1.6 pounds that are usable to potentially burn fuel, not 2 pounds like you had before. The box is still full to the top. You have the same pressure, the same volume (so the same FLOW), but less oxygen available to burn fuel.

All of this assumes you have a box with no hole in it.

Your engine is this box with a hole in it. Well, I guess your intake manifold is, but you get the idea. The faster your engine is turning, the bigger the hole gets. This is where flow rate comes into play. The faster your engine runs, the more flow the turbo has to provide to establish the same pressure ratio. That's why small turbos run out up top- because they can't move enough air to maintain pressure against the engine once the engine is gobbling up more air.

Addressing points:

1. Yes, pressure is pressure- but assuming everything else is the same. LHO has to assume that both setups have engines of the exact same displacement running at the same speed. With a 2 liter engine running at a constant 4000rpm, a turbo pushing 4psi against it is always pushing the same volume of air, no matter what the turbo size. Pressure is pressure.

2. On the bigger turbo making the same amount of power but just at a different RPM, that makes no sense. LHO is already stating that the larger turbo will make boost at a higher engine speed than the smaller turbo, and that's correct. Everyone knows that. Assuming the same efficiency, a small turbo pushing 10psi at 5000rpm will make half as much power as a turbo pushing 10psi at 10000rpm. Both engine setups are making the same amount of torque- they're both burning the same amount of fuel per engine revolution- but since the 10000rpm engine is applying that force twice as fast as the 5000rpm engine, it makes twice as much power. Easy. So... if the larger turbo is making the same pressure as the smaller turbo but does it higher up in the rev range of the engine, then it will make more power at the same pressure level, not the same amount of power. That's just a function of engine speed.

I'm sure homie LHO would come back with something like "oh, the small turbo can make 10psi in the same place that the big turbo can," and he might be right- but then this is where all the efficiency fun comes into play. The small turbo might be able to push 10psi at 10k just like the bigger turbo, but it won't do it as efficiently as the larger turbo. Even at the same flow rate and the same pressure, the larger turbo will flow more MASS into the engine because it is operating more efficiently. The small turbo is just generating heat because it's out of range, while the larger turbo is working pushing more air. Same pressure, same CFMs, different mass flow rate, different power outputs.

3. See #1. 5psi is 5psi, assuming the engine is consuming air at the same speed in both cases (box with hole in it). You have a constant cross section for air to flow across, you have the same pressure differential, and you have the same amount of air going out. Everything is identical.

4. Yes, more flow = more power... generally. When you're reading the compressor maps for a turbocharger, they're mapped with pressure ratio vs flow rate. Just because a turbo can flow a certain amount of air volume doesn't mean that it can succesfully push that volume into an engine at a certain pressure. You could theoretically have a turbo that could push 500cfm, but only be capable of pushing it at 1psi. Any more resistance, and you don't get that flow rate. The turbo must have both the capability to flow the volume AND be able to maintain pressure to push it into an engine.

Also, talking about flow on its own without reference to the density of that flow is misleading. Flow on its own doesn't tell you anything. You can flow the same volume of light sugar water and thick molasses- and they will be the same flow rate- but you get totally different amounts of sweetness, right? I generally think that people who just talk "oh but this one FLOWS more CFMs" without mentioning efficiencies or air densities doesn't fully understand what they're talking about.

5. See efficiency.

6. Yay T&A! Talking about compressor maps... but it's not just the volume vs pressure that are important- the efficiency islands are the most important part of the compressor map.

-----

So basically- T&A is a lot more right than LHO, but LHO is technically right in most of his stuff. He just doesn't have the whole picture.

I hope that clears things for some people and doesn't muddy the waters for too many....

Turbo&Auto

Nick Go FAST!!

Thanks for the writeup, I need to read it a couple more times to fully soak it all in. Some of it I do know, but a lot is new and good info

I realize about efficiency and somewhat how to read a compressor map, still learning that aspect of turbocharging. I couldnt get to that point with this guy though, he didnt want to hear anything but 4psi is 4psi and you cant make anymore power at the same psi no matter the turbo. I got a bit derailed and skirted some of the more important issues. We were also assuming them to be on the same motor within the same kind of group of turbos too. Like T25's, GT28's. The guy Wish that I was talking about has a Matrix like mine and originally had a T25 on it, he swapped out to a Big16G equivelant turbo and pickeed up a lot of power without anymore boost. He couldnt understand how that was possible and I was just lacking all the terminology to get it across properly.

Thanks for the info, you rly can never learn too much about turbos. If you have any other sites that you could point me to for reading info I would appreciate it. I google the shit, but you get a mixed bag of peoples opinions and whats actually real.

I realize about efficiency and somewhat how to read a compressor map, still learning that aspect of turbocharging. I couldnt get to that point with this guy though, he didnt want to hear anything but 4psi is 4psi and you cant make anymore power at the same psi no matter the turbo. I got a bit derailed and skirted some of the more important issues. We were also assuming them to be on the same motor within the same kind of group of turbos too. Like T25's, GT28's. The guy Wish that I was talking about has a Matrix like mine and originally had a T25 on it, he swapped out to a Big16G equivelant turbo and pickeed up a lot of power without anymore boost. He couldnt understand how that was possible and I was just lacking all the terminology to get it across properly.

Thanks for the info, you rly can never learn too much about turbos. If you have any other sites that you could point me to for reading info I would appreciate it. I google the shit, but you get a mixed bag of peoples opinions and whats actually real.

MikeBergy

Blah blah blah....

lol. Mike, I have been in the process of writing this exact same writeup for the last couple of hours. Then I ran into this post while taking a mental break. how odd. I guess we have both been thinking about the noobs with all their PSI questions. You put out good points. The box with the hole in it analogy is great. I like to think of it as water-in-water-out. If you have a compressor that can maintain a set pressure within the same efficiency island (i.e. 14psi) from the time it is fully spooled up to the engine's redline, then you are good, provided that you aren't lagging too much. If your turbo moves away from the higher efficiency island, you'll start heating up the intake temps, lowering intake air density.

If you want to size a turbo correctly, you gotta do the calcs. It's not too much work. Here is a good site that has a lot of compressor maps available. Turbo and Supercharger Maps

If you want to size a turbo correctly, you gotta do the calcs. It's not too much work. Here is a good site that has a lot of compressor maps available. Turbo and Supercharger Maps

Turbo&Auto

Nick Go FAST!!

I've read it a few times now, its starting to sink in more and more and make more sense too. I think I'm starting to see the whole picture instead of a narrow view of what doesnt matter as much.

I'm still hazy on compressor maps though. Every place I read trying to figure out how to read a compressor map misses all kinds of important factors. Do you have a site that clearly can explain how to read a compressor map?

I'm still hazy on compressor maps though. Every place I read trying to figure out how to read a compressor map misses all kinds of important factors. Do you have a site that clearly can explain how to read a compressor map?

MikeBergy

Blah blah blah....

Okay. It's pretty easy if you know what all the math mumbo jumbo means.

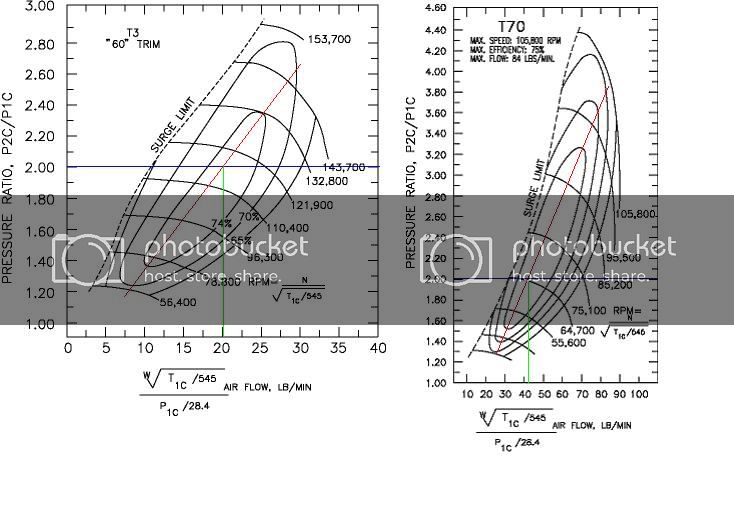

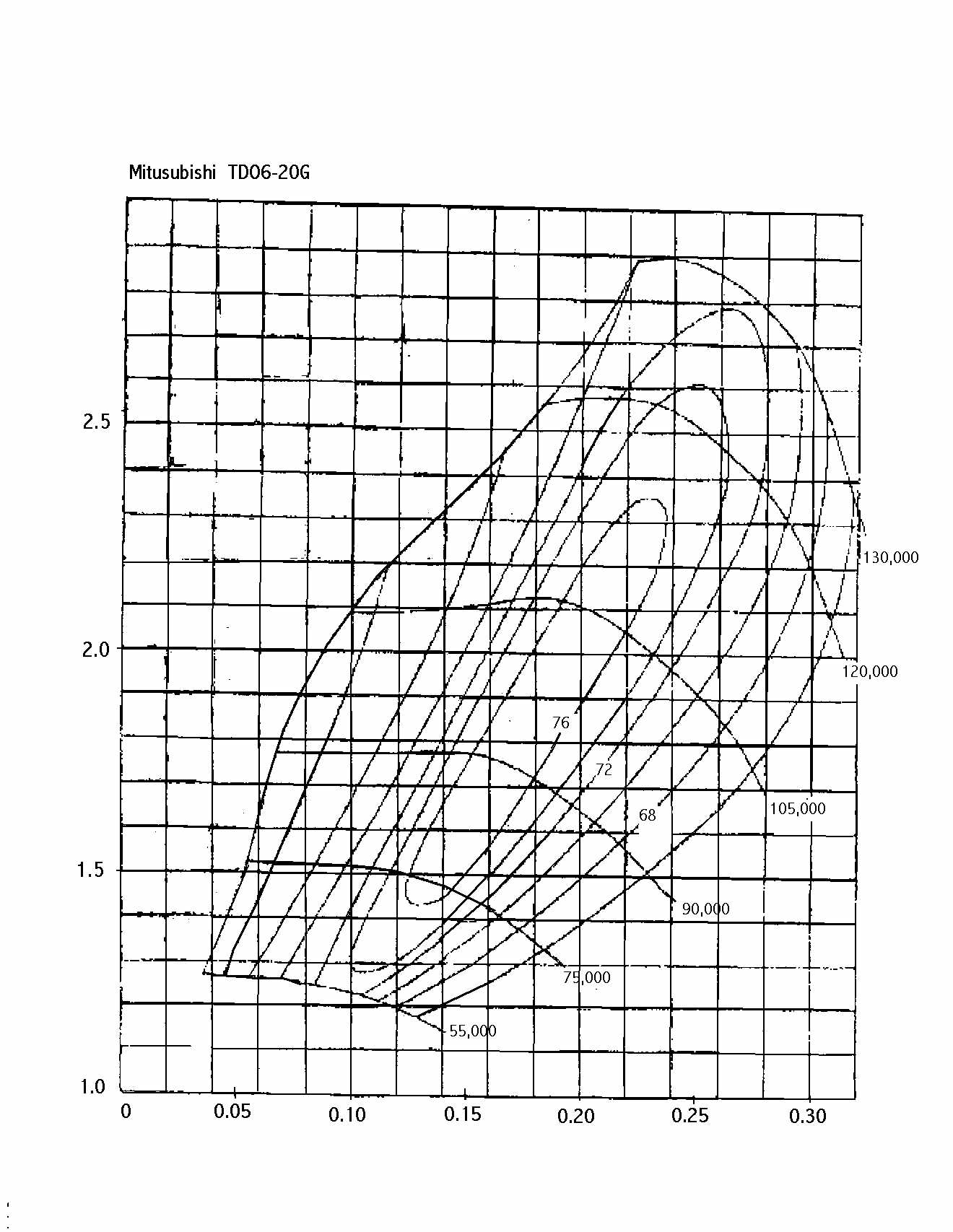

These particular maps compare a t3 'super 60' compressor and a t70 compressor. I picked the t70, because it has been showing up a few times over the past week or so.

Start with the vertical axis. The vertical axis displays the outlet:inlet pressure ratio. For example - if the inlet is at atmospheric standard, and you read 2.0 on the chart, the exit pressure will be twice standard atmospheric pressure, which 29.4psi absolute, or 14.7 psi gauge. Gauge pressure is what you will see on the boost gauge if it is an SAE gauge.

Next, the horizontal axis. This is simply the MASS flow of the compressor, corrected for standard temperature and pressure. 'w' is a standard symbol for mass flow. (T1c/545)^.5 is the correction for standard temperature, where T1c is the ambient temperature of the air at the compressor inlet in degrees Rankine. P1c/28.4 is correction for standard pressure.

Temperature and pressure corrections are commonly shown in equations as the greek symbols theta and delta respectively. I have honestly never seen 28.4 used in the delta term, as standard pressure is 14.7 psia, so I am thinking it may be a typo. Regardless, the corrected flow is just a way to comparing compressor performance test results from two different climates, say florida and california, whose average atmospheric temperature and pressure will be fairly different at each location. They are just used to get everything on the same page, number wise. Here is some literature on corrected flow. Gas Semantic Definition: Corrected Mass Flow

Now to the graph. You'll notice there are concentric circular blobs drawn on the page. These are called efficiency islands. While the areas within each area may not be exactly a certain efficiency, it can be said that within each island, efficiency is equal to or greater than that which is shown on the line. For example, any operating point of the compressor within the innermost island on the super 60 map will operate with at least 74% efficiency. That is to say, 74% of the work done on compressor by the turbine shaft will actually compress the air. The rest of the work will be turned into heat. The higher the efficiency, the better. This is pretty straightforward.

The lines moving somewhat horizontally across the graph are lines of constant rotor RPM, corrected of course. These are just lines showing how pressure ratio of the compressor varies directly with mass flow given a constant rpm. Not really useful imo in regards to applying it to anything, but it's there.

Far left, you'll see a surge line. You've heard of compressor surge, no doubt. Basically this is the point at which the rotor blades will stall, causing a drop in pressure ratio. As the pressure ratio drops, the blades begin moving air again. Then, it proceeds to cycle itself between stalled and unstalled conditions. This creates pressure pulses which can really screw things up mechanically, because the compressor is no longer steady state, and is pretty much out of control.

I created a couple of lines for comparison of the two maps. The red line is a typical operating line along which a compressor will most likely be operating. Compressors are much more likely to follow a path of greatest efficiency. I just showed that at a single operating point of 14.7 psig (p2/p1 = 2.0), the t70 is capable of flowing MUCH more air than a 'super 60' t3, about twice as much.

As Mike said, the engine only sees manifold pressure, and intake temperature. You could be boosting 12 psi on both compressors from the time the turbo spools up to the engines redine. But the difference lies in the efficiency islands. You may be pushing 12psi to both systems, but the super 60 might be adding 20% more heat to the intake charge than the t70.

The t70 is a huge beast. It's not a good choice for small honda applications, as it would take so much exhaust gas flow to spool it up, you'd be near your redline before you even achieved a desirable boost level.

Last edited:

w0rd! I should get the $50 article cash for that one post.

I'm glad it helped you.

I'm still trying to figure turbos out. The compressor side is easy- but what I want to know is how to crunch to the math on the spool characteristics of a given turbocharger. That's a lot more difficult... you have to take into account the drag on the turbine from the amount of work the compressor is doing, then deal with exhaust velocity, density and temperature. Fun stuff. I think Bergy probably knows why I would be wanting to know how to calculate spool characteristics...

That guy you were arguing with on the board knew some good basics, but he was still missing most of the picture- even though he thought he knew it all. We all have lots to learn.

Heh. Mike and Mike both engineers (well, you're still in school ), both thinking about posting the same information. Gotta love it.

), both thinking about posting the same information. Gotta love it.

I teach by analogy. I've found that it works well, especially since I'm always trying to explain really complicated ideas to non-technical people (like Katie). It's also one of the most effective ways to teach 6th grade kids complex concepts in chemistry and physics. That was a fun bunch of years. It's badass when you get a 10 year old to truly understand the Bernoulli effect, the math behind chemical reactions, centrifugal force, distributed loading etc. It's a good feeling.

So you like the box with the hole in it huh? I'll have to write up a series of more formal articles and post them up somewhere.

Sinking in is good.

Mike's explanation of the compressor map reading is pretty good. There really isn't much to it. Once you understand how to look at the map, you'll slap yourself in the forehead and go "duh."

Thanks homie.

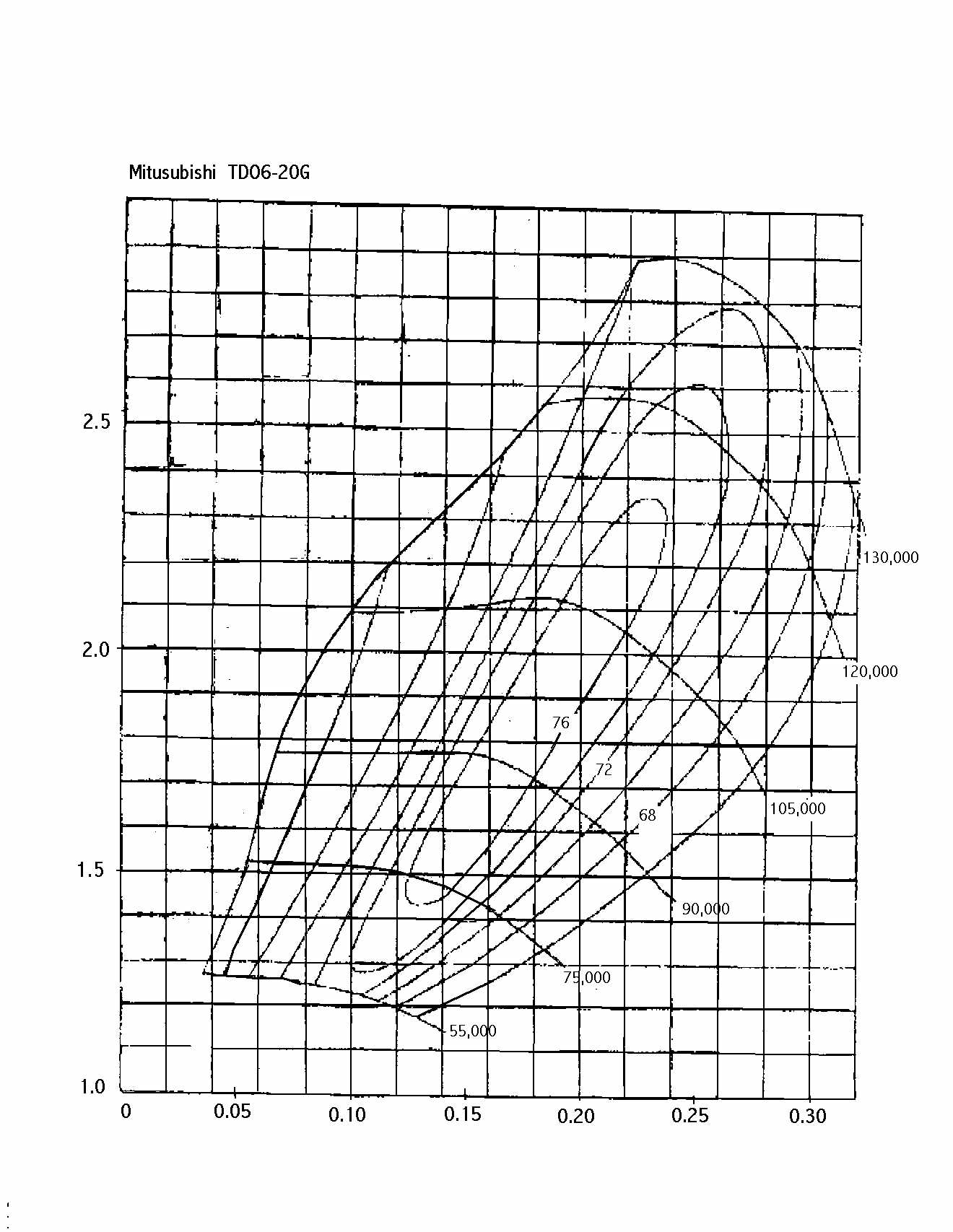

Mike- good writeup on reading compressor maps! I created an Excel sheet that I use to approximate volume and mass flows based on engine displacement, intake temp, and constant volumetric efficiency (uh oh, another concept to explain!). I apply that information to the compressor maps to get a rough idea of how an engine will perform.

Here's a little something I made a while back to size up a 1G DSM 14b turbo to the Nissan Hardbody's KA24E engine. There are a few assumptions- constant volumetric efficiency for one- so it's not a perfect real world approximation, but it's close enough to get a rough idea of how things should fall:

The graph isn't all that clear on its own, but hopefully the lines and how things sit give you an idea of how to estimate the operating range of a turbocharger vs a specific engine.

Turbo&Auto said:Thanks for the writeup, I need to read it a couple more times to fully soak it all in. Some of it I do know, but a lot is new and good info

I realize about efficiency and somewhat how to read a compressor map, still learning that aspect of turbocharging. I couldnt get to that point with this guy though, he didnt want to hear anything but 4psi is 4psi and you cant make anymore power at the same psi no matter the turbo. I got a bit derailed and skirted some of the more important issues. We were also assuming them to be on the same motor within the same kind of group of turbos too. Like T25's, GT28's. The guy Wish that I was talking about has a Matrix like mine and originally had a T25 on it, he swapped out to a Big16G equivelant turbo and pickeed up a lot of power without anymore boost. He couldnt understand how that was possible and I was just lacking all the terminology to get it across properly.

Thanks for the info, you rly can never learn too much about turbos. If you have any other sites that you could point me to for reading info I would appreciate it. I google the shit, but you get a mixed bag of peoples opinions and whats actually real.

I'm glad it helped you.

I'm still trying to figure turbos out. The compressor side is easy- but what I want to know is how to crunch to the math on the spool characteristics of a given turbocharger. That's a lot more difficult... you have to take into account the drag on the turbine from the amount of work the compressor is doing, then deal with exhaust velocity, density and temperature. Fun stuff. I think Bergy probably knows why I would be wanting to know how to calculate spool characteristics...

That guy you were arguing with on the board knew some good basics, but he was still missing most of the picture- even though he thought he knew it all. We all have lots to learn.

MikeBergy said:lol. Mike, I have been in the process of writing this exact same writeup for the last couple of hours. Then I ran into this post while taking a mental break. how odd. I guess we have both been thinking about the noobs with all their PSI questions. You put out good points. The box with the hole in it analogy is great. I like to think of it as water-in-water-out. If you have a compressor that can maintain a set pressure within the same efficiency island (i.e. 14psi) from the time it is fully spooled up to the engine's redline, then you are good, provided that you aren't lagging too much. If your turbo moves away from the higher efficiency island, you'll start heating up the intake temps, lowering intake air density.

If you want to size a turbo correctly, you gotta do the calcs. It's not too much work. Here is a good site that has a lot of compressor maps available. Turbo and Supercharger Maps

Heh. Mike and Mike both engineers (well, you're still in school

I teach by analogy. I've found that it works well, especially since I'm always trying to explain really complicated ideas to non-technical people (like Katie). It's also one of the most effective ways to teach 6th grade kids complex concepts in chemistry and physics. That was a fun bunch of years. It's badass when you get a 10 year old to truly understand the Bernoulli effect, the math behind chemical reactions, centrifugal force, distributed loading etc. It's a good feeling.

So you like the box with the hole in it huh? I'll have to write up a series of more formal articles and post them up somewhere.

Turbo&Auto said:I've read it a few times now, its starting to sink in more and more and make more sense too. I think I'm starting to see the whole picture instead of a narrow view of what doesnt matter as much.

I'm still hazy on compressor maps though. Every place I read trying to figure out how to read a compressor map misses all kinds of important factors. Do you have a site that clearly can explain how to read a compressor map?

Sinking in is good.

Mike's explanation of the compressor map reading is pretty good. There really isn't much to it. Once you understand how to look at the map, you'll slap yourself in the forehead and go "duh."

reikoshea said:okay, so there was a lot to write.

good work yizzle.

Thanks homie.

MikeBergy said:Okay. It's pretty easy if you know what all the math mumbo jumbo means.

Mike- good writeup on reading compressor maps! I created an Excel sheet that I use to approximate volume and mass flows based on engine displacement, intake temp, and constant volumetric efficiency (uh oh, another concept to explain!). I apply that information to the compressor maps to get a rough idea of how an engine will perform.

Here's a little something I made a while back to size up a 1G DSM 14b turbo to the Nissan Hardbody's KA24E engine. There are a few assumptions- constant volumetric efficiency for one- so it's not a perfect real world approximation, but it's close enough to get a rough idea of how things should fall:

The graph isn't all that clear on its own, but hopefully the lines and how things sit give you an idea of how to estimate the operating range of a turbocharger vs a specific engine.

nice write ups guys, excellent info

now if i could just find a map for my IHI turbo

lol

now if i could just find a map for my IHI turbo

lol

Turbo&Auto

Nick Go FAST!!

Thanks for the rundown. What was puzzeling me when I looked at maps was the fact that you need to add atmospheric pressure to the equation. I would convert 10psi to the equivelent used on the chart and it wouldnt even be on the map. Then yesterday I added 14.7 to the amount of boost I planned on running and things started to make a LOT more sense.

Thanks again for the writeups guys, I rly love to read about turbos and how everything works. I seem to learn at least 2 things everytime I sit down and read more and more.

Edit: After looking at that 14b map, I'm glad I went with a larger turbo. It would've choked out early. The Big16G I'm using will make good power without a lot of heat around 10-12 and then be much more efficient in the area I want to track the car at, 15-17psi. BUT, it does look like I could've still went larger.

Thanks again for the writeups guys, I rly love to read about turbos and how everything works. I seem to learn at least 2 things everytime I sit down and read more and more.

Edit: After looking at that 14b map, I'm glad I went with a larger turbo. It would've choked out early. The Big16G I'm using will make good power without a lot of heat around 10-12 and then be much more efficient in the area I want to track the car at, 15-17psi. BUT, it does look like I could've still went larger.

Last edited:

Turbo&Auto

Nick Go FAST!!

This 20G might be better suited for more HP and a better drag turbo.

I know someone selling one soon too.....hmmmm......

I know someone selling one soon too.....hmmmm......

lmao, you're a boost addict...

Similar threads

- Replies

- 22

- Views

- 8K

- Replies

- 1

- Views

- 2K