Andrew

Active Member

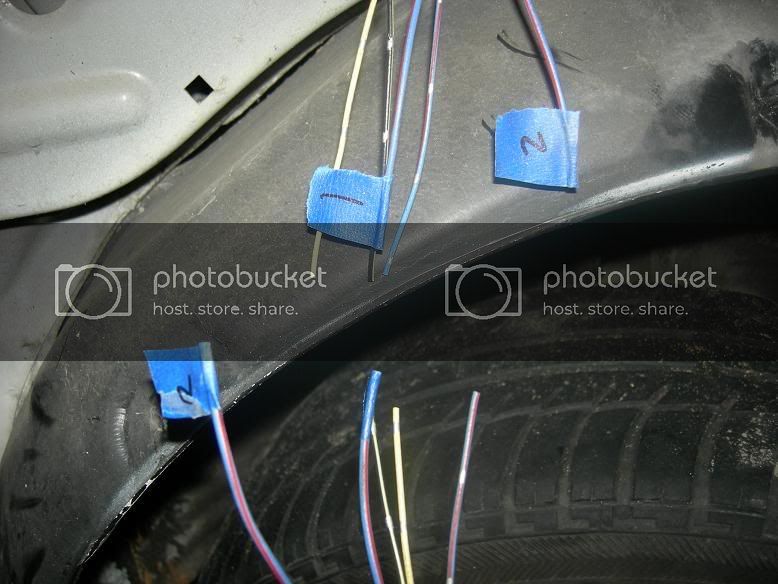

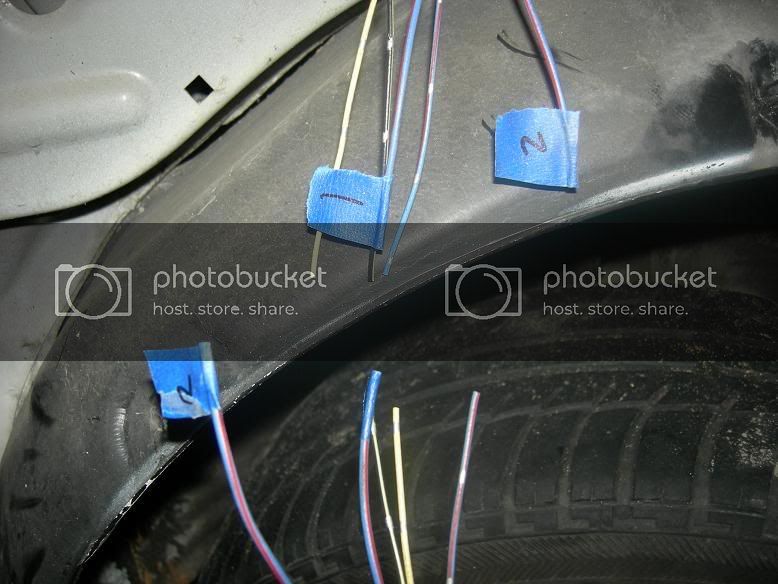

Well, since my motor is shipped off to KMS Engine Development, I figure I have about a month to get my engine bay looking sweet... So I decided to try my hand at a wire tuck. However, I'm not going all out and moving the fusebox into the cabin, I'm just hopeing to relocate it out of site, just so I don't have to go through all that hassle. (At least thats my plan as of now. we'll see how confident I feel after this easy stuff  )

)

On with it:

I'm gonna let the pictures do most of the talking.

And this is how it sits right now:

And thats that for now.

The plan for today is to get it washed up and start prepping for paint.(re-painting it white to clean it up.)

Updates soon!

-Andrew

On with it:

I'm gonna let the pictures do most of the talking.

And this is how it sits right now:

And thats that for now.

The plan for today is to get it washed up and start prepping for paint.(re-painting it white to clean it up.)

Updates soon!

-Andrew