Awesome thanks for sharing! Hows it feel on the street?

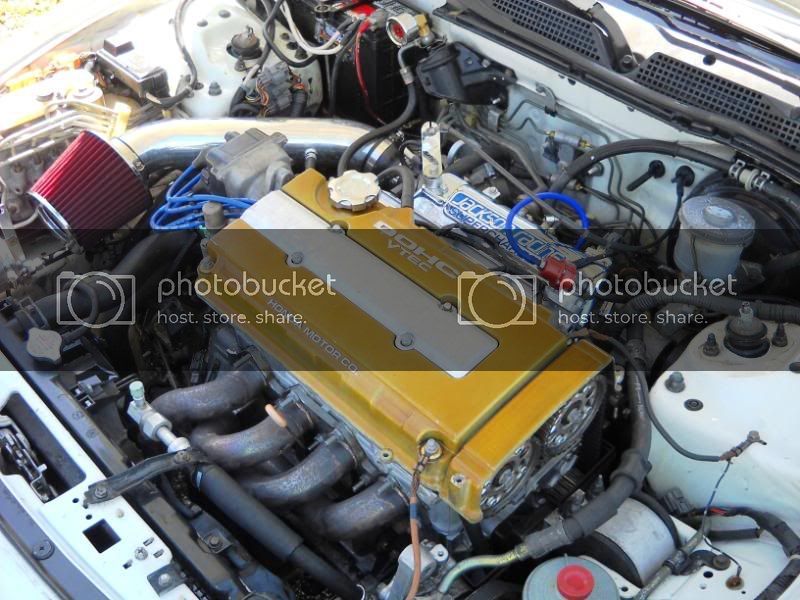

Is it me or does your motor move way too much when you let off the gas? What are you doing for motor mounts?

i thought that same thing.. looked like that fucker was about to jump out of the bay and pimp smack someone