LS_VTEC

you get the BRAKE

sweet sweet.. i just said that cuz i pieced mine together so i used that engine assembly stuff it took me like 4 months to piece it together... but its looking good... let us know how it runs... you gonna get it tuned?

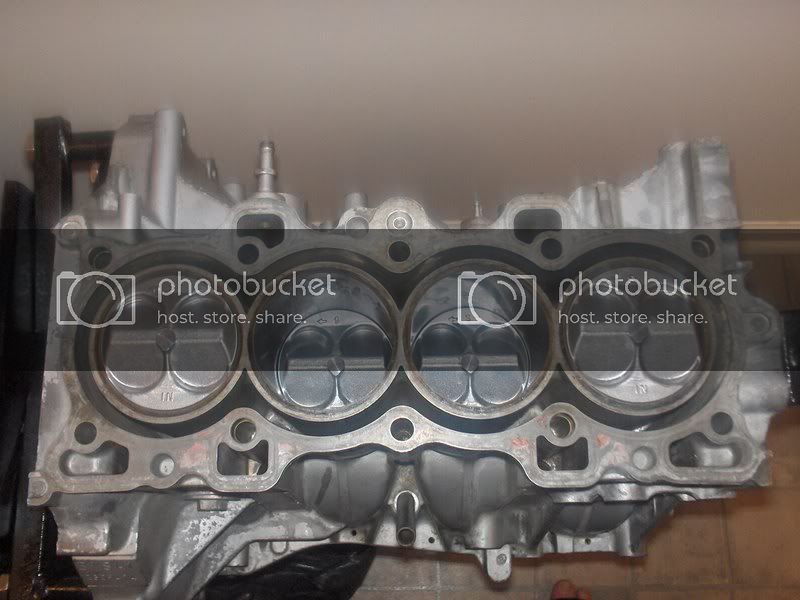

Will do, video's and all after the break-in. It should be all said and done within the next couple weeks, hopefully I don't get any snow here (NJ), it will set me back since the transmission and the head are still on the b16, which is still in the hatch.

As far as the tune goes, I contacted John Vega from phearable.net and he will be chipping a p28 for my particular setup. This will be temporary, mainly until after its broken in. I plan on taking it to my local tuner, Mike Miranda for tuning @ E-Shift. He tunes with crome-pro, so that is what I will be running as far as engine management goes. Oh yea, bigger injectors as well for that tune.