achir21

New Member

hi there honda fans !

i'm going through my 1st crvtec build, i'm gonna do it right, on the 1st time, and i wanna share my experiences with you.

of course the build isn't gonna start now, as im waiting for parts to arrive

in mean a little ride on my garage:

My Civic, not the pretiest one on this forum, but the chassis/suspnsion and the interior are both in good shape!

bur where is what.

it give's you an idea of the previous owner, sleep baby.... coz ur gonna be twisted

Let's check upstairs

hey that ali baba's cave...... jdm one....

when i say twisted, twisted .... a B20Z1

.... a B20Z1

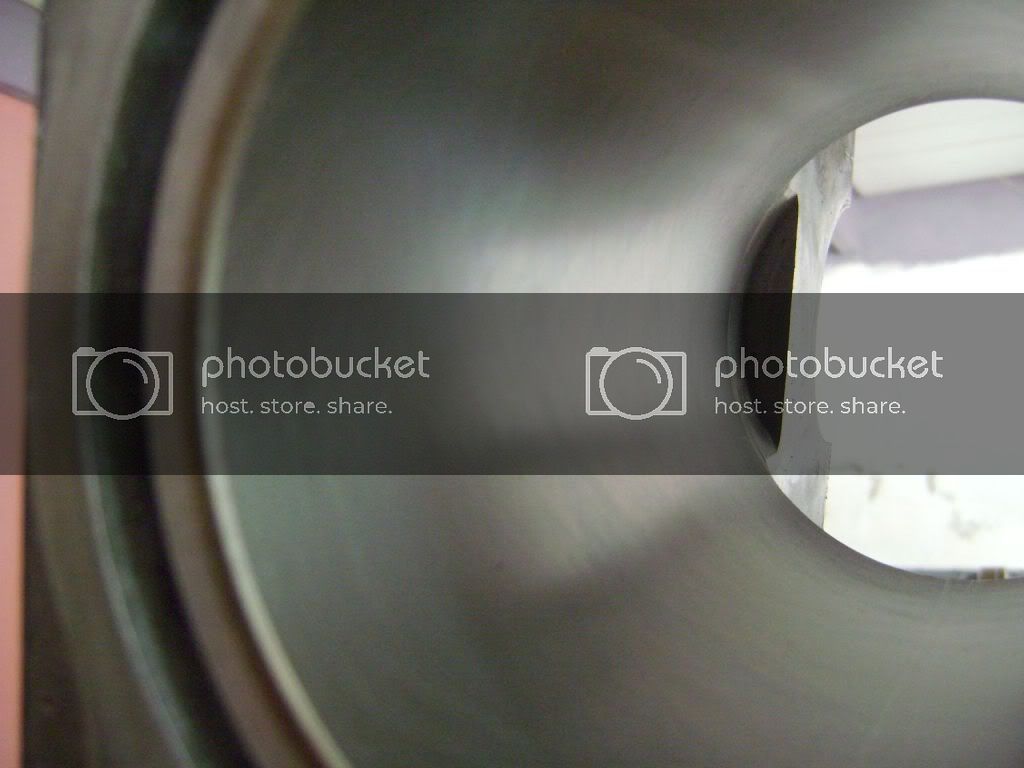

it cost me a lot, but the block in good shape, cylinders are still in spec

i've done a deglazing

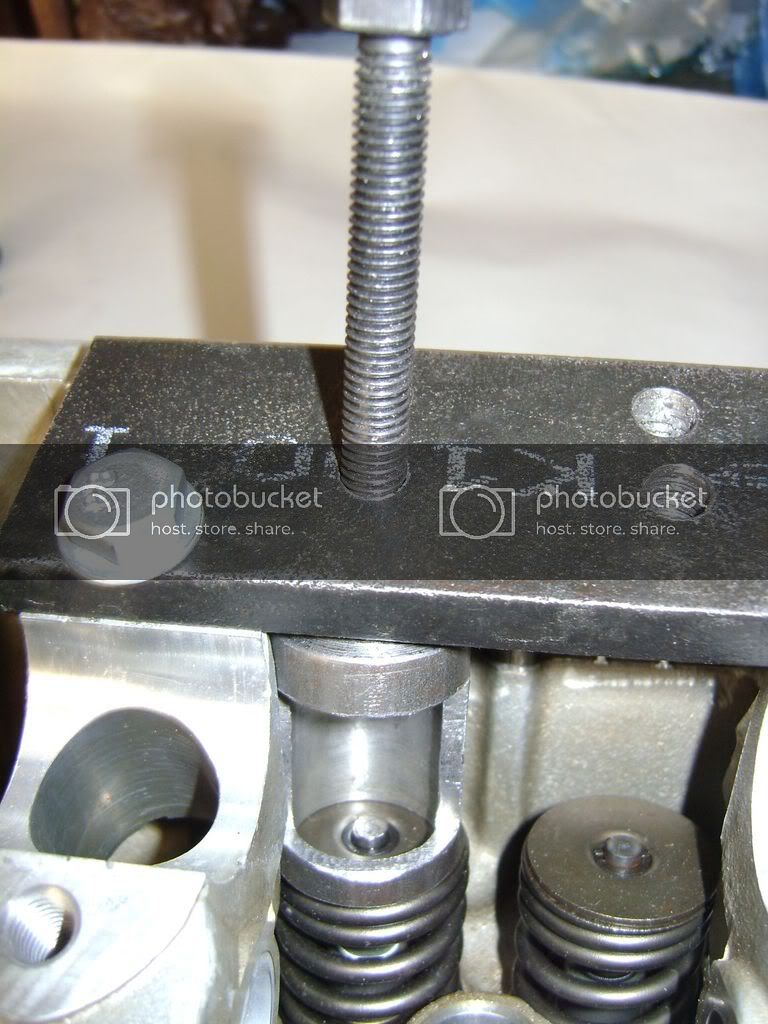

the B16A2 Head

didn't resist to put the head on the block, juste to see how it looks like...

kick some ass, no doubts, Honda best inline 4 !

ALL the remaining engine parts were cleaned, plastifed, and arranged in this cupboard

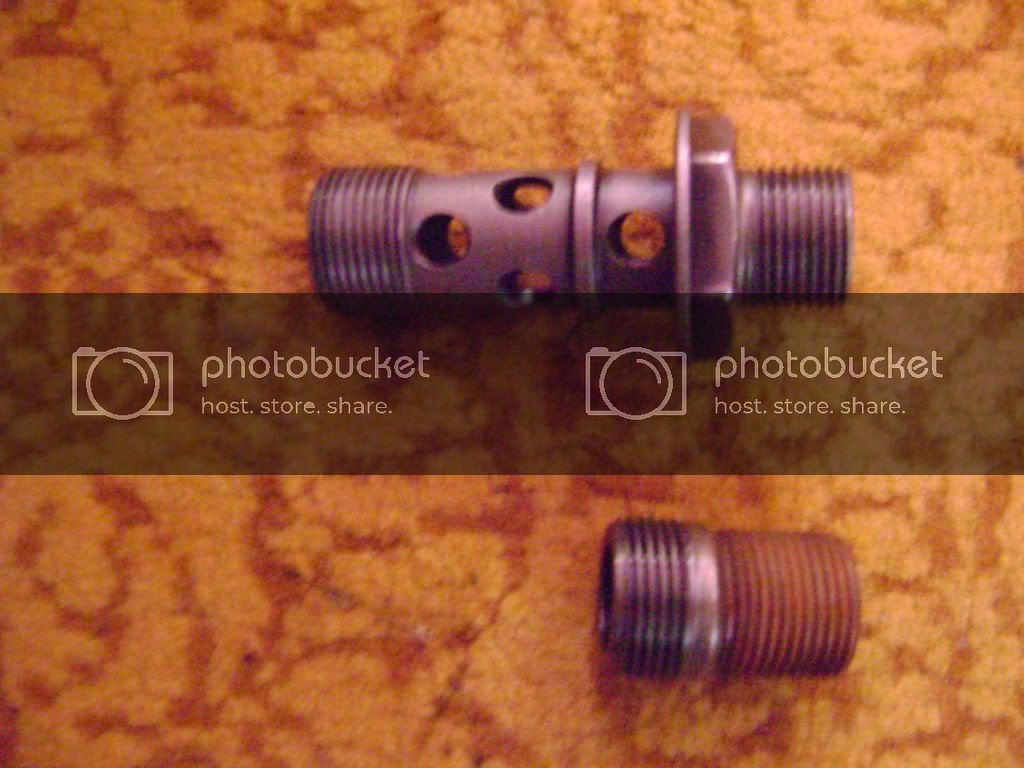

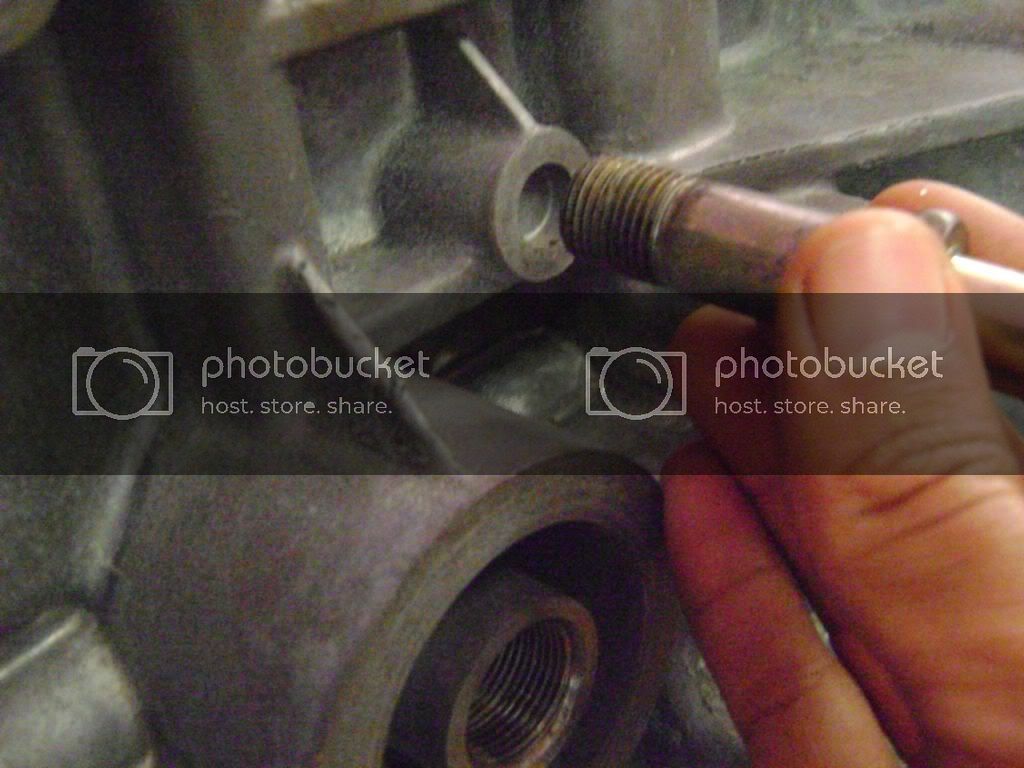

almost new crank ! !

i love this tranny, shame it doesn't have an LSD..... maybe one day !

so i'm planning to make a reliable engine, with stock internals except for the rod bolts, wanna make power aound 6k ~ 7k ..... so my head and mainfold are juste pefect for the job !

same for the compression, don't wanna go more than 10.5 so stock pistons are good for me, thats becoz we don't have high grade gas on our country.....

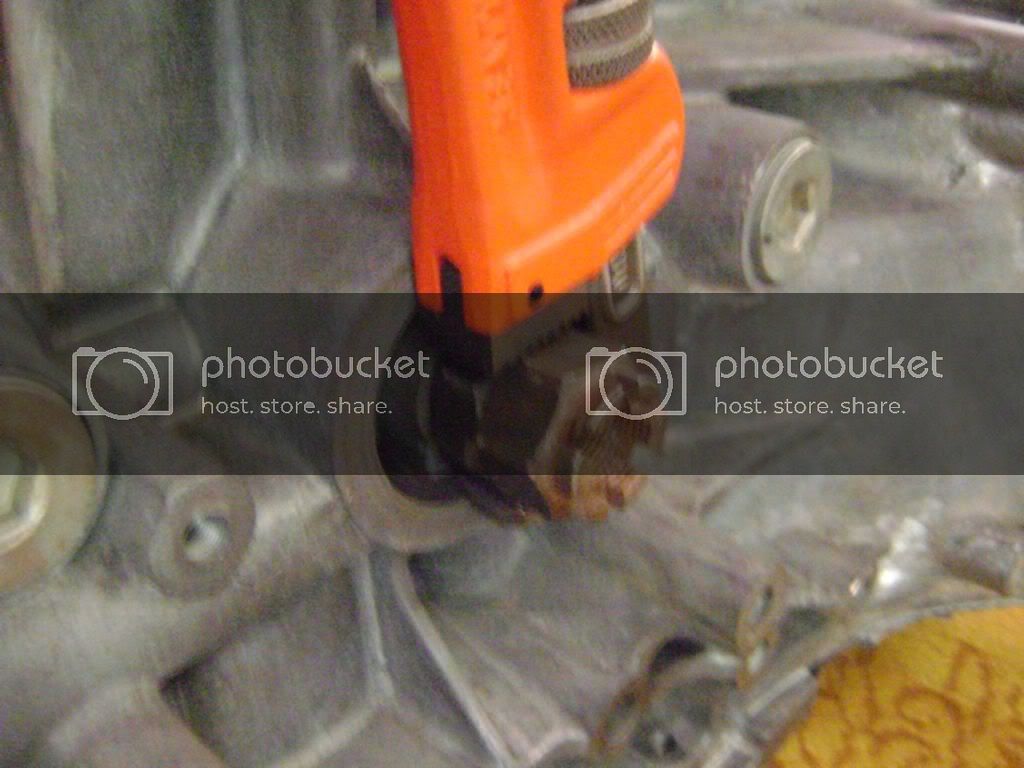

i'll be reconditioning my valve seat, with my self as the machinists don't have the proper tools ..... anyway many little things to do.... but no biggy :

..... anyway many little things to do.... but no biggy :

i'll be posting while i'll be working .... thx 4 watching

.... thx 4 watching

i'm going through my 1st crvtec build, i'm gonna do it right, on the 1st time, and i wanna share my experiences with you.

of course the build isn't gonna start now, as im waiting for parts to arrive

in mean a little ride on my garage:

My Civic, not the pretiest one on this forum, but the chassis/suspnsion and the interior are both in good shape!

bur where is what.

it give's you an idea of the previous owner, sleep baby.... coz ur gonna be twisted

Let's check upstairs

hey that ali baba's cave...... jdm one....

when i say twisted, twisted

it cost me a lot, but the block in good shape, cylinders are still in spec

i've done a deglazing

the B16A2 Head

didn't resist to put the head on the block, juste to see how it looks like...

kick some ass, no doubts, Honda best inline 4 !

ALL the remaining engine parts were cleaned, plastifed, and arranged in this cupboard

almost new crank ! !

i love this tranny, shame it doesn't have an LSD..... maybe one day !

so i'm planning to make a reliable engine, with stock internals except for the rod bolts, wanna make power aound 6k ~ 7k ..... so my head and mainfold are juste pefect for the job !

same for the compression, don't wanna go more than 10.5 so stock pistons are good for me, thats becoz we don't have high grade gas on our country.....

i'll be reconditioning my valve seat, with my self as the machinists don't have the proper tools

i'll be posting while i'll be working