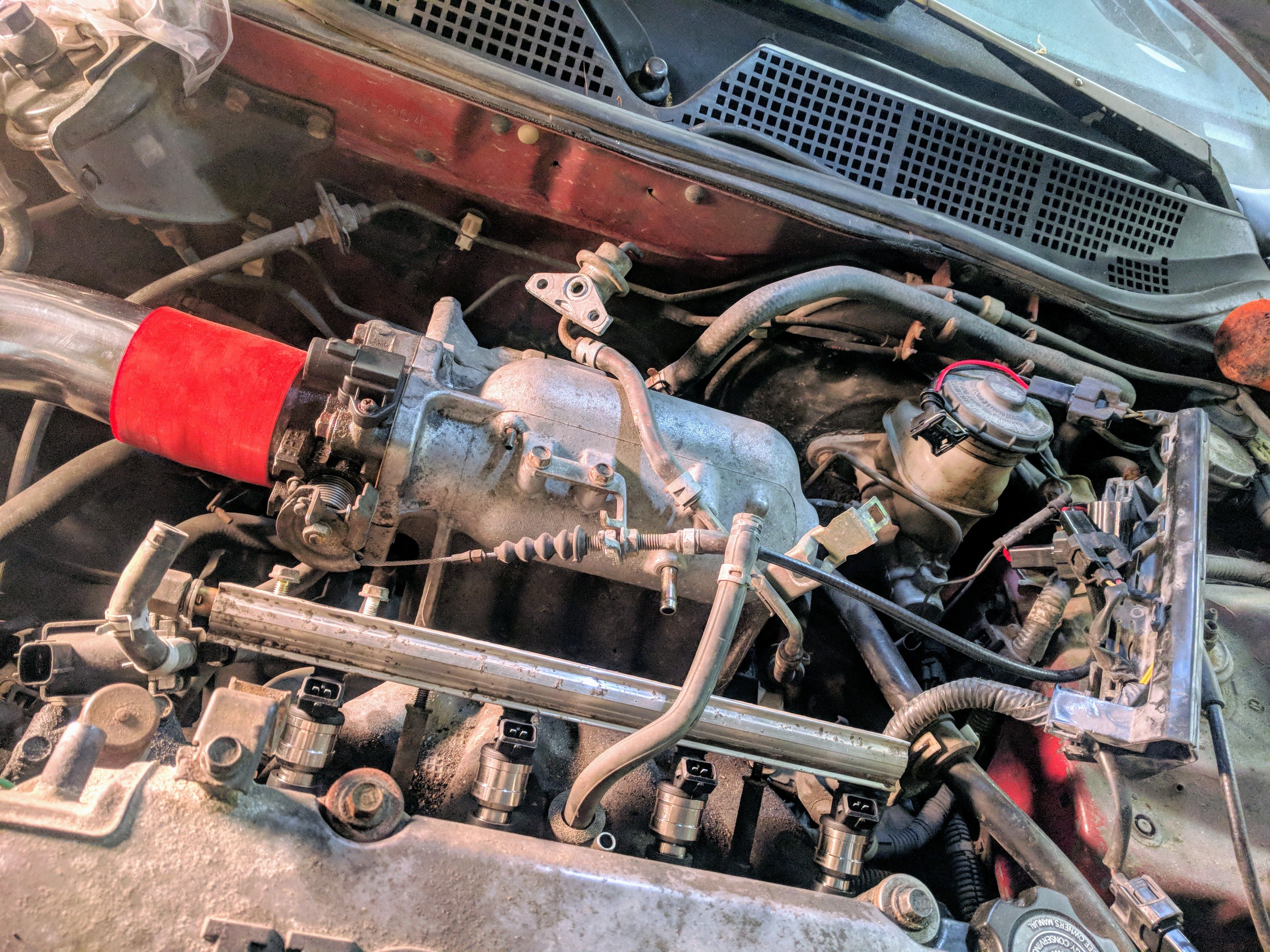

you couldnt even clean it first?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The white-mess, my EM1 Si with a d16y8.

- Thread starter awptickes

- Start date

- Replies 413

- Views 48K

We may earn a small commission from affiliate links and paid advertisements. Terms

I'm just test fitting everything, once it all fits, I'll clean everything and put it back together.

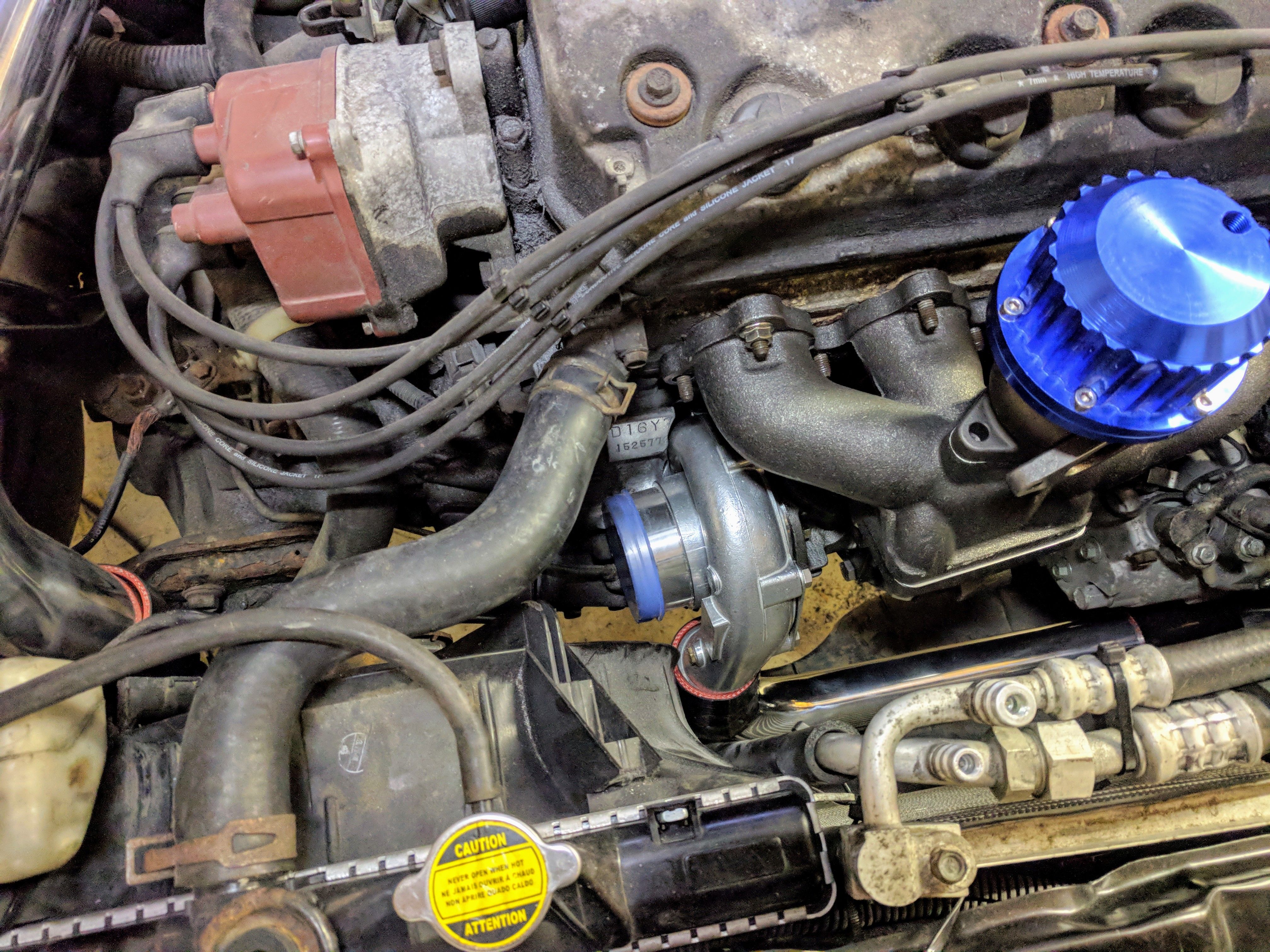

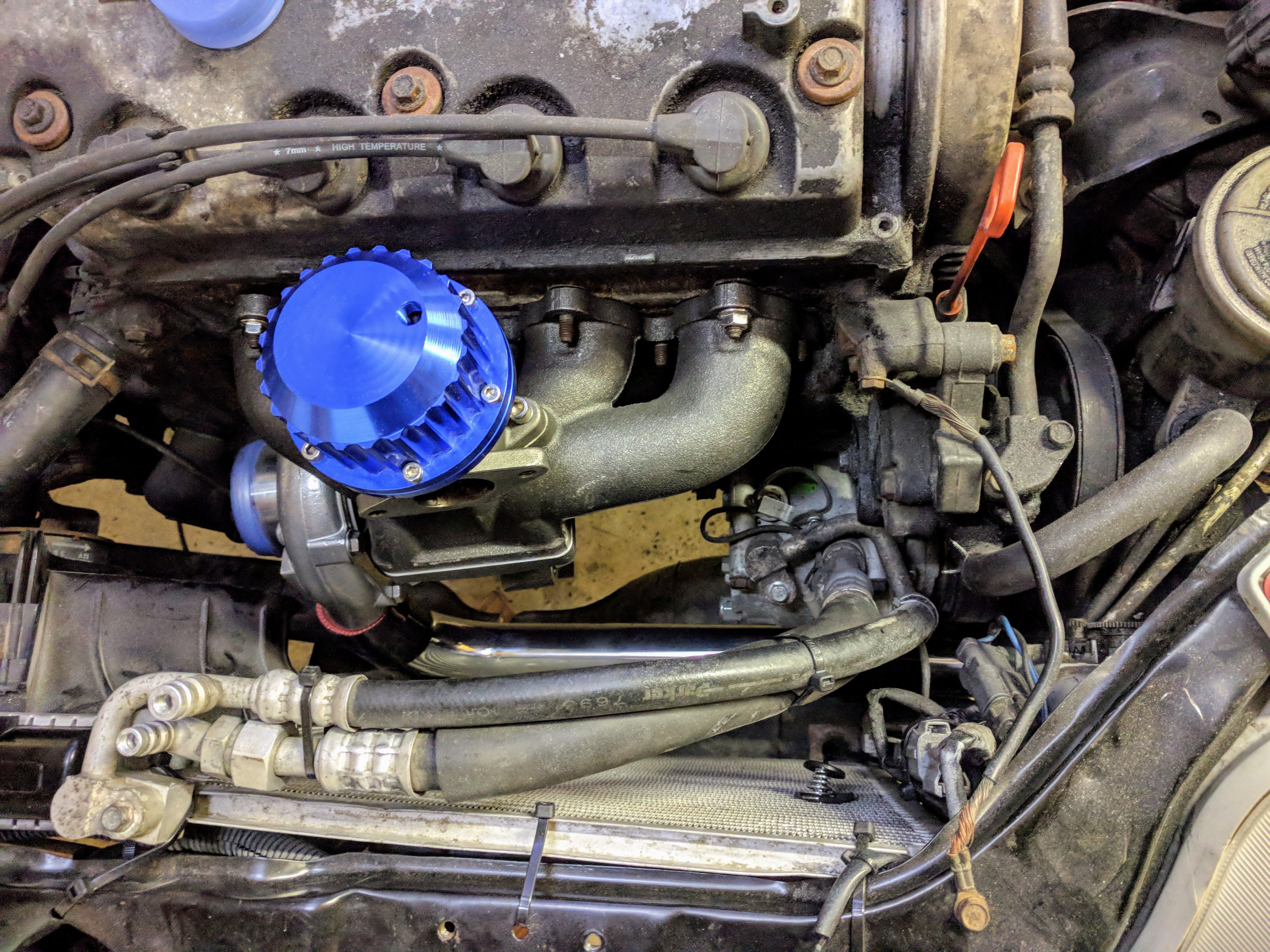

Anyway, I got the charge piping installed fitted up, turbo fitted, clocked, and the block webbing ground away enough for the turbo to fit. The down pipe arrived today, I got a few minutes to test fit it, only to realize that I don't have bolts to put it on the turbo exhaust housing. Oops. I'm not totally sure the exit flange actually mates to the stock exhaust, it seems like it is rotated 45-deg ccw to what I need.

I get the new oil feed line tomorrow, the one came with all this stuff doesn't seem trustworthy...

So, tonight I'm hoping to find some bolts that work the the turbo housing and get the 550cc injectors and 4bar MAP sensor installed. Then, if I have time, weld up a wastegate dump tube.

Tomorrow I'd like to find time to wash out and degrease the engine and engine bay before I change the oil and do the oil feed and drain lines. Then do final assembly -- Maybe it'll happen, lol.

Pics, as promised:

Anyway, I got the charge piping installed fitted up, turbo fitted, clocked, and the block webbing ground away enough for the turbo to fit. The down pipe arrived today, I got a few minutes to test fit it, only to realize that I don't have bolts to put it on the turbo exhaust housing. Oops. I'm not totally sure the exit flange actually mates to the stock exhaust, it seems like it is rotated 45-deg ccw to what I need.

I get the new oil feed line tomorrow, the one came with all this stuff doesn't seem trustworthy...

So, tonight I'm hoping to find some bolts that work the the turbo housing and get the 550cc injectors and 4bar MAP sensor installed. Then, if I have time, weld up a wastegate dump tube.

Tomorrow I'd like to find time to wash out and degrease the engine and engine bay before I change the oil and do the oil feed and drain lines. Then do final assembly -- Maybe it'll happen, lol.

Pics, as promised:

Shiny parts!

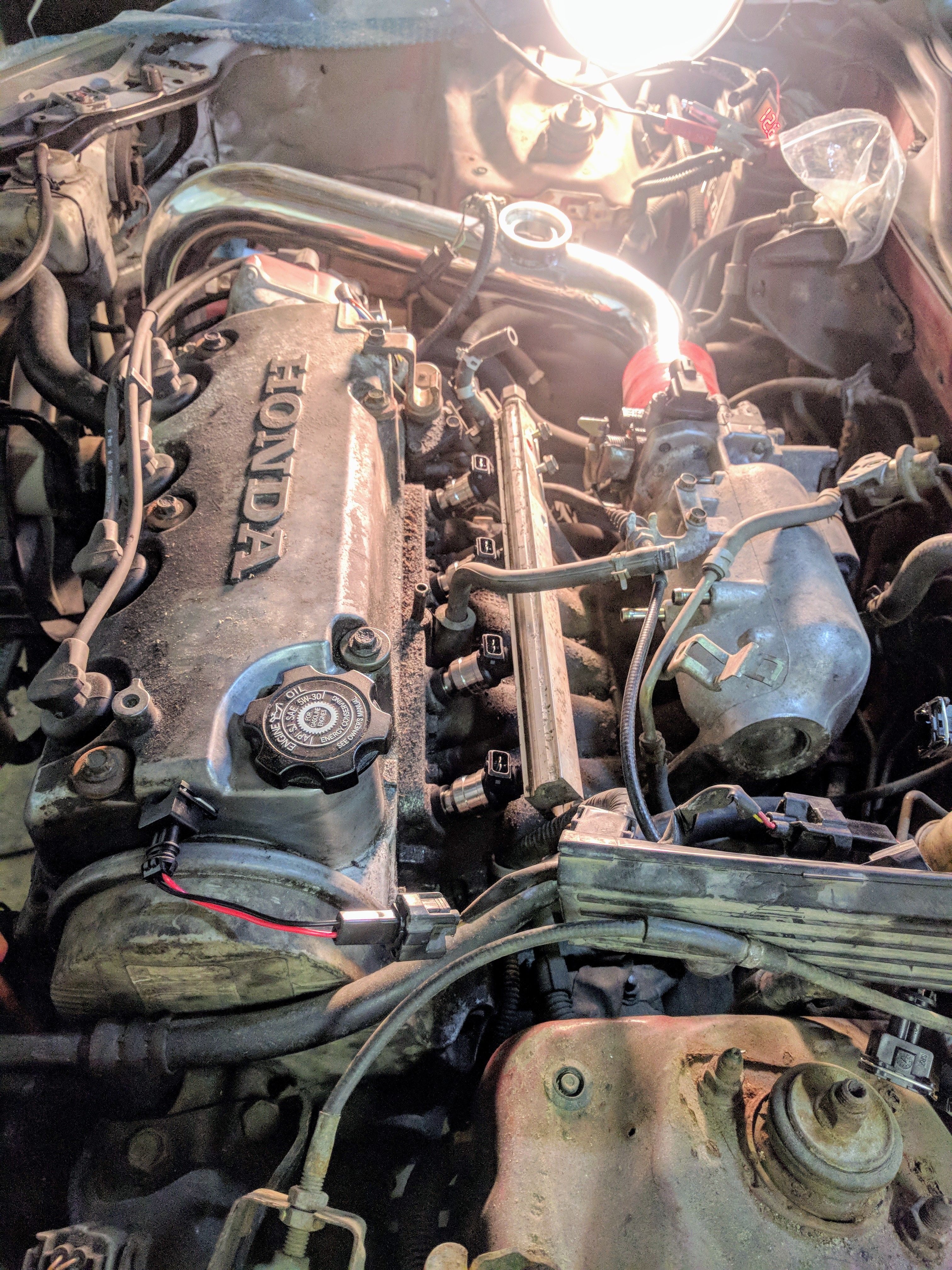

Got the injectors and MAP sensor installed this morning. For today, I'm going to finish the PCV/catch can stuff, throw some bolts in the turbine housing to get the down pipe bolted up, and get the wastegate dump tube welded up today. If there's time, I'll put heat wrap on the down pipe.

I'm leaving the stock fuel pressure regulator, going to leave the EVAP stuff in for now. Neither should be an issue with the power levels I'm shooting for.

I'm leaving the stock fuel pressure regulator, going to leave the EVAP stuff in for now. Neither should be an issue with the power levels I'm shooting for.

Well, the blow off valve c-clip is too thick, so I'm gonna have to get a new one.

The down pipe turbo flange is rotated clockwise about 8 degrees too far, even after I gently removed some more material from the block and the A/C bracket. So I'm going to have to cut that off and reweld it.

The down pipe turbo flange is rotated clockwise about 8 degrees too far, even after I gently removed some more material from the block and the A/C bracket. So I'm going to have to cut that off and reweld it.

Can’t shave the clip? Most knockoff hks have the same problem... as did mine. I shaved it a bit and it held fine.

Also put a cap or tape over the hole just Incase. You never know!

Also put a cap or tape over the hole just Incase. You never know!

Can’t shave the clip? Most knockoff hks have the same problem... as did mine. I shaved it a bit and it held fine.

Also put a cap or tape over the hole just Incase. You never know!

I went to Ace Hardware and got another 2" c-clip. This one works fine but I hope I never have to get it out. I also picked up some M8-1.25 bolts for the turbo exit, but that doesn't matter right now, because:

Gasp! The eBay Down Pipe doesn't fit!

I mean, it almost fits... The angles are right to clear the AC compressor, it would almost mate up to the "catalytic converter" if the flange were oriented correctly... I dropped a line to the eBay seller asking if it's a defect, or this is how all of them are. I don't expect a response, but eBay has got my back, it's clearly not fitting correctly, and the auction said it would.

I ordered a new T4 5-Bolt flange from Amazon, and it'll be here Monday. I may just run an open made out of flex-tube and a pair of 90-degree pre-fab bends. If it comes down to it. I just want to get this car on the road, I don't have to get it on the road any time soon.

Oil system is still incomplete, I wanted to get the downpipe fitted so I could see how to route the oil lines safely. I've got two different oil feed kits, and enough AN fittings and line so that should be done buying parts.

I may be putting another slim fan on the car for the radiator, because the 2.5" compressor inlet piping doesn't fit well with the factory fan on there. It's unfortunate, but I may have to replace that one too.

Interesting:

http://hondavert.ru/s300/

http://hondavert.ru/s300/

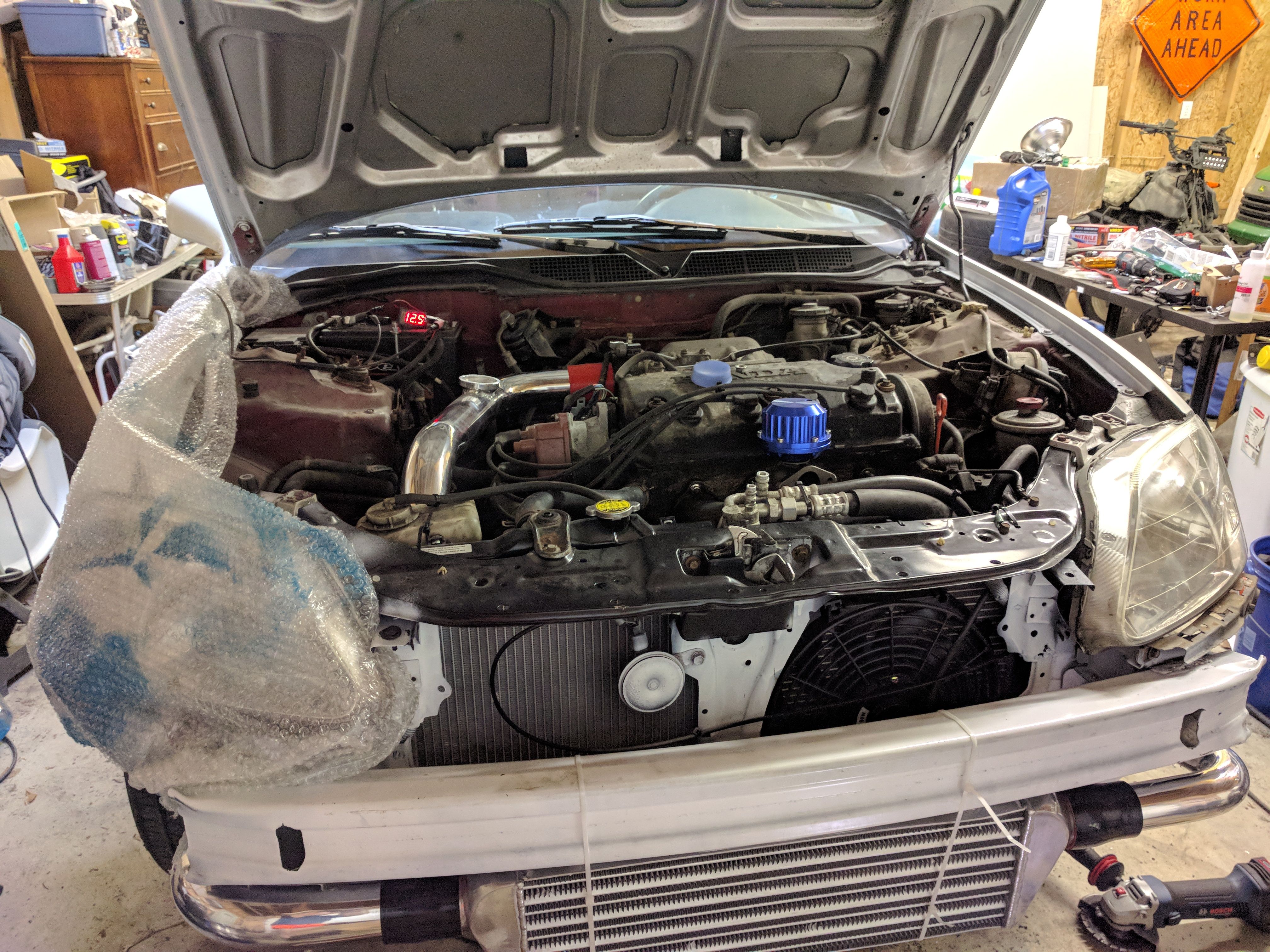

Got the intercooler bolted to the crash bar, and the bumper innards trimmed so it fits with the bumper on.

I forgot to close the hood, so it looks worse than it is.

And maybe I'll run the compressor inlet tubing this way, to get some not-so-hot air from outside the engine bay:

I forgot to close the hood, so it looks worse than it is.

And maybe I'll run the compressor inlet tubing this way, to get some not-so-hot air from outside the engine bay:

Well, I called around. Shops want about $300 just to think about making a downpipe. So... Plan B.

I welded it up. Basically I walked into a fab shop for aircraft fueling systems, off the street, showed it to them, they talked a bit to me about it and the more senior guy said "uh, we don't so much TIG. If you can weld, I'll setup the machine over there and you can do it." So I sat in this shop, used their super fancy water cooled tig with all kinds of fancy pre and post flow, and got it welded. used a rod and a half of filler, about 1/2" of tungsten, and got her done. After about 90 minutes of welding, I have a working downpipe and I owe them a 12-pk of Yeungling.

Jeb and the other guy are good people. They didn't want anything, but I told them I'm bringing beer, and when the car is done I'll bring it by.

Don't get me wrong, it's ugly. But that thin stainless tubing was unforgiving...

I welded it up. Basically I walked into a fab shop for aircraft fueling systems, off the street, showed it to them, they talked a bit to me about it and the more senior guy said "uh, we don't so much TIG. If you can weld, I'll setup the machine over there and you can do it." So I sat in this shop, used their super fancy water cooled tig with all kinds of fancy pre and post flow, and got it welded. used a rod and a half of filler, about 1/2" of tungsten, and got her done. After about 90 minutes of welding, I have a working downpipe and I owe them a 12-pk of Yeungling.

Jeb and the other guy are good people. They didn't want anything, but I told them I'm bringing beer, and when the car is done I'll bring it by.

Don't get me wrong, it's ugly. But that thin stainless tubing was unforgiving...

Got it fitted up, got some exhaust work done. I'm going to put a stock-looking muffler on it, and I've got the old 2.5" stainless exhaust from cars past. This downpipe is short, meaning, the collector flange is about 4" too far fore to connect to the mid-pipe. I'm going to make a piece to connect that, and be done with it.

Got the turbo bolted up, charge piping is in its final locations, just need to put the hose clamps on, I'll probably do that tonight.

The door cards from lrbracing.com came in, and they look nice:

I'll get the passenger one installed as soon as I fix the passenger window. I think there's a break in the harness. I've tried switching both switches, master and passenger, and I've tried cleaning the door connection connectors, but that's not helping. So, it looks like I'm gonna peel back the rubber protectors and trace them out one by one, can you tell I'm not looking forward to that?

I pulled the spring out of the wastegate, only to find out my garage scale (the one I use for charging A/C) doesn't work anymore, so we're just gonna hope it's a 7 or a 10 pound spring, lol.

I still need to install the oil lines for the turbo. Again, another task I'm not looking forward to doing, lol.

I'll probably install the catch can tonight.

Got the turbo bolted up, charge piping is in its final locations, just need to put the hose clamps on, I'll probably do that tonight.

The door cards from lrbracing.com came in, and they look nice:

I'll get the passenger one installed as soon as I fix the passenger window. I think there's a break in the harness. I've tried switching both switches, master and passenger, and I've tried cleaning the door connection connectors, but that's not helping. So, it looks like I'm gonna peel back the rubber protectors and trace them out one by one, can you tell I'm not looking forward to that?

I pulled the spring out of the wastegate, only to find out my garage scale (the one I use for charging A/C) doesn't work anymore, so we're just gonna hope it's a 7 or a 10 pound spring, lol.

I still need to install the oil lines for the turbo. Again, another task I'm not looking forward to doing, lol.

I'll probably install the catch can tonight.

Last edited:

Got the exhaust mocked up, pieces trimmed to bolt everything up to the downpipe, just need to weld it up tomorrow.

Installed the catch can, it looks like the pcv needs to be replaced, I suppose I'll buy one tomorrow. It's hooked up to the head vent and the PCV with the vacuum source being the compressor inlet. I just zip tied it to the AC lines for now, I'm going to have to make a bracket for it.

I got the turbo drain line figured out, oil pan drilled, and now I just have to weld that as well. I'm welding an AN10 bung on it. Hopefully one of the garbage AN10 45° fittings won't be total garbage, and it'll spin, tighten, seal, and otherwise work correctly.

I had to pick up an AN4 90° fitting to get the turbo feed to fit, and it has to be fed from the passenger side. So, I may need more than 40" of line to feed it, which sucks because all I have is a 36" and 40" line.

Left to do:

-Weld up exhaust pieces to make the down pipe fit the mid pipe.

-Weld up the drain fitting on the oil pan. I'll probably just TIG Braze it with silicon bronze filler, to reduce warp and heat.

-Weld or clamp up an extension to the wastegate to get it out of the engine bay.

-Change the oil, attach the turbo feed line, replace the PCV

-Put the colder plugs in.

-Connect the wbo2 and figure out if I want to run a narrowband.

-Connect the lines for the wastegate, blow off valve, and boost gauges.

-Drill charge pipe and insert IAT gauge.

-Connect the ECU, load the basemap, and start it up to check for leaks.

-Reinstall the passenger fender, bumper, other plastic thing, and the fender liners.

-Try not to blow it up data logging enough to street tune it well enough to drive to the dyno 20 miles away.

-Schedule Dyno time to tune it.

I should be done by the fourth of July.

Installed the catch can, it looks like the pcv needs to be replaced, I suppose I'll buy one tomorrow. It's hooked up to the head vent and the PCV with the vacuum source being the compressor inlet. I just zip tied it to the AC lines for now, I'm going to have to make a bracket for it.

I got the turbo drain line figured out, oil pan drilled, and now I just have to weld that as well. I'm welding an AN10 bung on it. Hopefully one of the garbage AN10 45° fittings won't be total garbage, and it'll spin, tighten, seal, and otherwise work correctly.

I had to pick up an AN4 90° fitting to get the turbo feed to fit, and it has to be fed from the passenger side. So, I may need more than 40" of line to feed it, which sucks because all I have is a 36" and 40" line.

Left to do:

-Weld up exhaust pieces to make the down pipe fit the mid pipe.

-Weld up the drain fitting on the oil pan. I'll probably just TIG Braze it with silicon bronze filler, to reduce warp and heat.

-Weld or clamp up an extension to the wastegate to get it out of the engine bay.

-Change the oil, attach the turbo feed line, replace the PCV

-Put the colder plugs in.

-Connect the wbo2 and figure out if I want to run a narrowband.

-Connect the lines for the wastegate, blow off valve, and boost gauges.

-Drill charge pipe and insert IAT gauge.

-Connect the ECU, load the basemap, and start it up to check for leaks.

-Reinstall the passenger fender, bumper, other plastic thing, and the fender liners.

-Try not to blow it up data logging enough to street tune it well enough to drive to the dyno 20 miles away.

-Schedule Dyno time to tune it.

I should be done by the fourth of July.

I think most of all.... i envy your spare time. what you've done in 3 weeks would have taken me a year, even if i had any mechanical ability

I don't really have all that much spare time, I just can't be stationary... It's excruciating to be sitting in the house all day, or do nothing all day.

How do you have time with a 2 year old?

My wife is a saint and the nicest person I know, she takes care of my daughter pretty much all day. My 2.5 year old loves going to harbor freight, auto parts stores, and loves seeing the car and anything that moves under its own power. Right now she's sick, so it's easier to find time, but not much. She goes to bed at 7pm every night, so I can work on the car a bit at night, and she has quiet time during the day after lunch to about 1:30 where she reads and plays quietly inside. But bottom line is that my wife is amazing and puts up with me and my hobbies.

Anyway, turbo has oil, return line, oil is changed, wbo2 is installed, boost gauge is temporarily installed, catch can is plumbed up, ECU is hooked up, basemap works to idle and rev in neutral. Idle isn't super consistent, but I've probably got a vacuum leak somewhere.

So, it runs, it idles, and it's almost ready to drive on the road. The laptop battery was almost dead from sitting in the garage for two weeks, but I did get the basemap loaded on the ostrich and got some data logged of me just sitting there on jackstands. It's a lot quieter than I remember turbo civic cars being... Even in a garage it's not super loud.

Tightened the OEM oil pressure switch tonight to take care of that leak and got a new PCV put in. Immediate difference in idle quality, and it looks like that will take care of the "engine and transmission covered in oil" problem.

I'm gonna give up on the passenger window for a while. It's just eating time I could be enjoying the car.

I'll weld up the exhaust to make the 2.5" stuff work with the 2.25" muffler or a 2.5" turndown, and then once I get it to where I can take it to an exhaust shop, I'll get them to make me stock looking 2.5" muffler/axle back to mate up with the exhaust.

Got the ASPX DIY-WB wbo2 LCD display, and I'm gonna hook that up and make a mount for it to 3d print. Then I get to figure out a boost gauge...

So, left to do:

-Install GM IAT sensor, since the honda one isn't reacting fast enough.

-Install the colder spark plugs.

-Weld up 2.5" pipes so they connect together. Probably will make a turn-down too, so I can run a cut out.

-Reinstall the passenger fender, bumper, other plastic thing, and the fender liners.

-Put the passenger side door trim panel on.

I'm almost ready to schedule dyno time... w00 w00. If I can get a good street tune, I'll just datalog and tweak as many runs as I can get in a couple hours, then go to Xenocron in NY at the end of June.

I wonder if I'll roast the 185 width Fuzion tires? Hahaha. Probably just one at a time.

I'm gonna give up on the passenger window for a while. It's just eating time I could be enjoying the car.

I'll weld up the exhaust to make the 2.5" stuff work with the 2.25" muffler or a 2.5" turndown, and then once I get it to where I can take it to an exhaust shop, I'll get them to make me stock looking 2.5" muffler/axle back to mate up with the exhaust.

Got the ASPX DIY-WB wbo2 LCD display, and I'm gonna hook that up and make a mount for it to 3d print. Then I get to figure out a boost gauge...

So, left to do:

-Install GM IAT sensor, since the honda one isn't reacting fast enough.

-Install the colder spark plugs.

-Weld up 2.5" pipes so they connect together. Probably will make a turn-down too, so I can run a cut out.

-Reinstall the passenger fender, bumper, other plastic thing, and the fender liners.

-Put the passenger side door trim panel on.

I'm almost ready to schedule dyno time... w00 w00. If I can get a good street tune, I'll just datalog and tweak as many runs as I can get in a couple hours, then go to Xenocron in NY at the end of June.

I wonder if I'll roast the 185 width Fuzion tires? Hahaha. Probably just one at a time.

looking good!!

Apparently the scaling tables don't work they way I thought they do in a Honda ECU, it reads the voltage drop across the sensor and there is no translation table. Derp. So I can't use the GM IAT sensor.

Instead, I tried threading the plastic sensor... Maybe it'll work. Probably not. It's probably going to pop out inner boost. I threaded it m12-1.25 because that's the first die I found in the box. I suspect I will wind up regretting the 25 minutes I spent on this at some point. I've got a CR-V IAT sensor coming in case it does wind up in regret.

I got the passenger door panel on with a speaker. So now I have four speakers in the car! Woohoo! I can listen to REM, RHCP, and Now! That's What I Call Music! (Original CD) in style, just like 1999.

I contacted a bunch of tuners, and nobody does crome anymore, even Xenocron. So it looks like I'm going to be buying dyno time and doing it myself.

Now I have the rest of the stuff left:

-Sparkplugs

-exhaust

-wideband display

-bumper, grille, fender liners

I hope to take it for a drive this Friday.

Instead, I tried threading the plastic sensor... Maybe it'll work. Probably not. It's probably going to pop out inner boost. I threaded it m12-1.25 because that's the first die I found in the box. I suspect I will wind up regretting the 25 minutes I spent on this at some point. I've got a CR-V IAT sensor coming in case it does wind up in regret.

I got the passenger door panel on with a speaker. So now I have four speakers in the car! Woohoo! I can listen to REM, RHCP, and Now! That's What I Call Music! (Original CD) in style, just like 1999.

I contacted a bunch of tuners, and nobody does crome anymore, even Xenocron. So it looks like I'm going to be buying dyno time and doing it myself.

Now I have the rest of the stuff left:

-Sparkplugs

-exhaust

-wideband display

-bumper, grille, fender liners

I hope to take it for a drive this Friday.

Last edited:

Apparently I forgot to put in a bigger fuel pump... So one will be here tomorrow, and then I'll be ready to drive it.

Bumper, grille, and fenders are on.

BUT, the wastegate hits the hood, so I still need to chip up the hood strength ribbing on the underside to get everything to close correctly. Since the bumper fits so horribly now with the intercooler, I don't have to worry about new hood hinges, because it'll never fit well, lol.

I also got the first part of the exhaust welded up. It's actually Silicon Bronze brazed, because I'm lazy and SiB is easier and quicker to work with. This goes from the down pipe collector to the midpipe. Left to weld is the wastegate dump, and the muffler flange.

The muffler is 2-1/4 inch, so we'll have to see how well that works... At least it'll be quiet when the wastegate isn't open, lol.

Bumper, grille, and fenders are on.

BUT, the wastegate hits the hood, so I still need to chip up the hood strength ribbing on the underside to get everything to close correctly. Since the bumper fits so horribly now with the intercooler, I don't have to worry about new hood hinges, because it'll never fit well, lol.

I also got the first part of the exhaust welded up. It's actually Silicon Bronze brazed, because I'm lazy and SiB is easier and quicker to work with. This goes from the down pipe collector to the midpipe. Left to weld is the wastegate dump, and the muffler flange.

The muffler is 2-1/4 inch, so we'll have to see how well that works... At least it'll be quiet when the wastegate isn't open, lol.

Similar threads

- Replies

- 3

- Views

- 3K

- Replies

- 10

- Views

- 11K

- Replies

- 4

- Views

- 3K

- Replies

- 14

- Views

- 3K