So once upon a time, I used to work doing repair work on coffee equipment. I liked the work but not so much the job as espresso machines was only a small part of it. I've been wanting to find a project and finally decided to pull the trigger on an old Astoria CKXE that I found for a decent price, not great, but decent. I wanted a rotary pump machine as I don't personally have much love for vibration pumps and also wanted a prosumer type of machine to replace my Breville that I have grown weary of.

Unfortunately, the machine was damaged in shipping as it was packaged by fedex in just a cardboard box, it weighs about 75lbs, with nothing for the base to rest on. Luckily, the seller was great and we worked out a partial refund and I was comfortable with keeping it, if it doesn't work out then I will use it as a parts donor. Primarily the damage is a large dent in the top corner as shown in the pictures, ruining the front panel and the corner of the top, and the bottom frame where the drip tray should be is bent upward. I think I may be able to get it bent back just enough to work fine, maybe. All of the legs got bent in the frame as well, the rubber feet aren't in great shape so I will replace them, unfortunately I will have to drill out the mounting holes and mount them in a different manner as the steel panel on the underside is bent where the legs mount in. The shipping damage has definitely complicated the matter of trying to fix it, but time will tell if its fully salvageable, mainly the warped front frame is the concern.

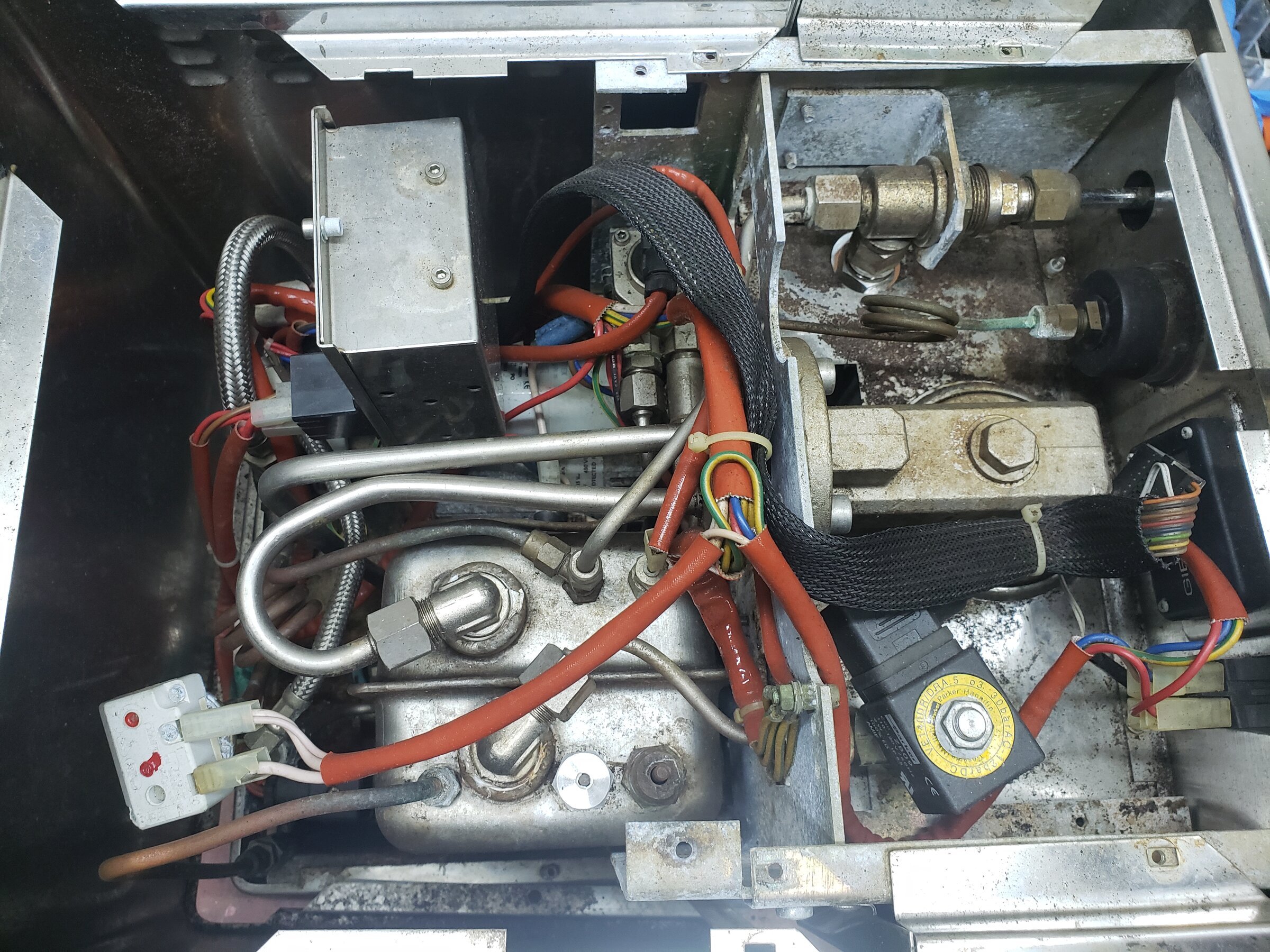

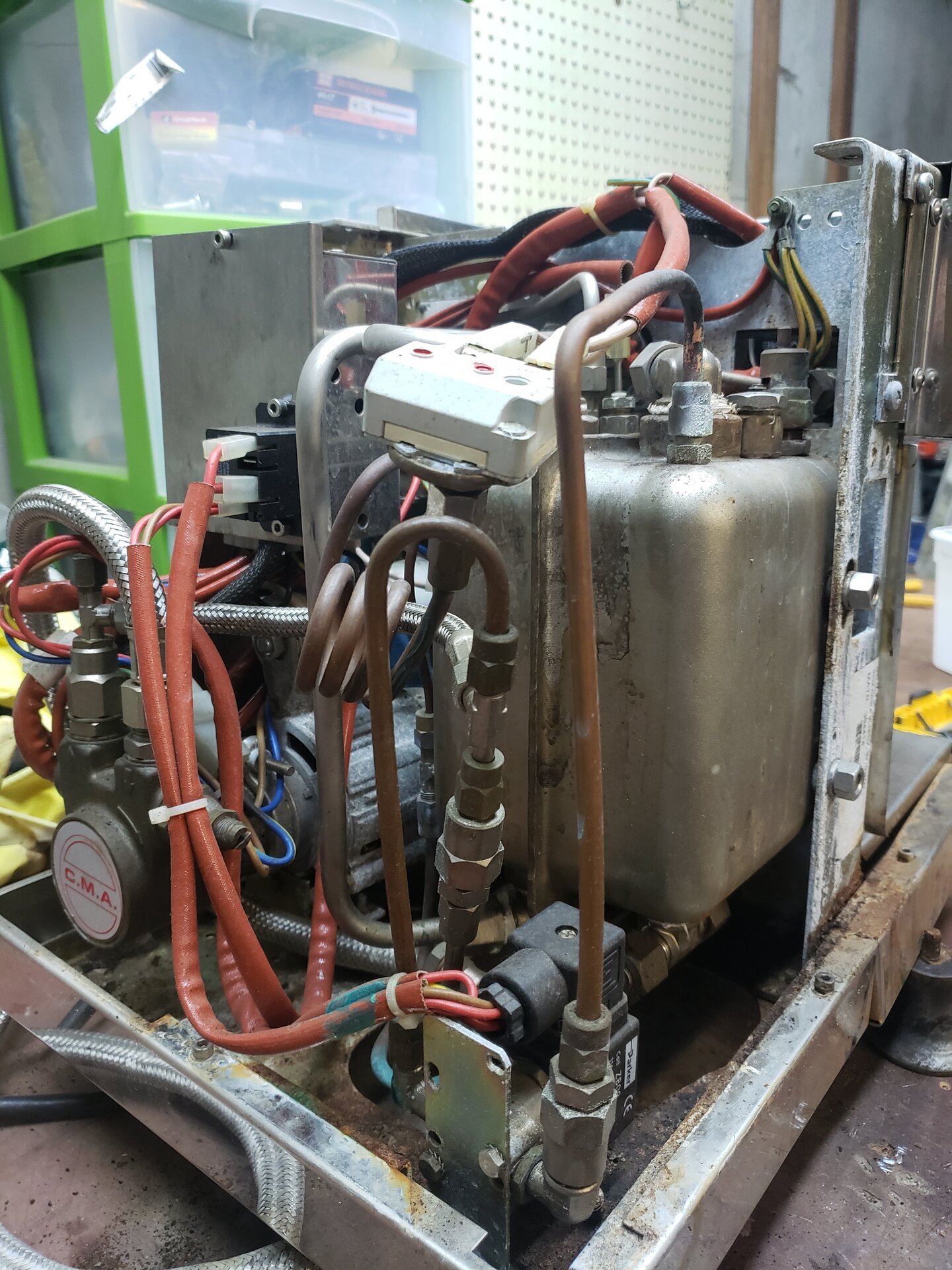

Thankfully, the inside looks pretty clean and everything looks to be accounted for. When plugged in, the power switch lights up, and pressing the dispense button activated the solenoid valve but the pump did not engage, not unexpected, it was sold as not working. This was not connected to a water supply when checking this, the power test was only about 5 seconds before shutting it back off, more testing will be done once water is connected. I removed the pump from the motor and it was not spinning at all, got that loosened up and free spinning and set aside.

Next picture shows the state of the drip tray area, it looks as though this machine was used quite a bit while missing the actual drip tray. I lost a little hope after removing the drip tray cover and the front panel thinking that the whole frame here was rusted through, but once I started vacuuming it out the "rust" came off easily and smelled like absolute hell, I'm pretty sure this was layers of milk and coffee that have dried over time. The last pic shows how well it came off with only gentle persuasion, there is hope.

That is where it stands now, this will be a slow moving project as my first goal is to get it working, then I will dismantle the whole and thing and sandblast the frame and soak everything in de-scaler and replace all of the seals and gaskets, still need to test the heating element as well. Luckily the rear body panel looks to have suffered minimal damage and is in good shape, a little polish and it will look great.

I'll enjoy this project as it can be done in my basement, comfortably standing or sitting on a stool at the workbench. No climbing, crawling, or crowding around a car in a small basement garage and no dust and extended cleanup like the wood working stuff. Can't do much woodwork in the basement as the dust may not work well with a gas powered furnace and water heater down there, don't want to risk anything. This is nice and compact and only issue will be any water leakage which can just be shut off and cleaned up enough to dry.

Plan is to try and hunt down the body panels, mainly the drip tray, and try to hammer the current ones straight. Make new legs out of some oak I have and just make it function. Want to replace the current steam pressure gauge with a dual pressure one so I can see the pump pressure while making espresso

Unfortunately, the machine was damaged in shipping as it was packaged by fedex in just a cardboard box, it weighs about 75lbs, with nothing for the base to rest on. Luckily, the seller was great and we worked out a partial refund and I was comfortable with keeping it, if it doesn't work out then I will use it as a parts donor. Primarily the damage is a large dent in the top corner as shown in the pictures, ruining the front panel and the corner of the top, and the bottom frame where the drip tray should be is bent upward. I think I may be able to get it bent back just enough to work fine, maybe. All of the legs got bent in the frame as well, the rubber feet aren't in great shape so I will replace them, unfortunately I will have to drill out the mounting holes and mount them in a different manner as the steel panel on the underside is bent where the legs mount in. The shipping damage has definitely complicated the matter of trying to fix it, but time will tell if its fully salvageable, mainly the warped front frame is the concern.

Thankfully, the inside looks pretty clean and everything looks to be accounted for. When plugged in, the power switch lights up, and pressing the dispense button activated the solenoid valve but the pump did not engage, not unexpected, it was sold as not working. This was not connected to a water supply when checking this, the power test was only about 5 seconds before shutting it back off, more testing will be done once water is connected. I removed the pump from the motor and it was not spinning at all, got that loosened up and free spinning and set aside.

Next picture shows the state of the drip tray area, it looks as though this machine was used quite a bit while missing the actual drip tray. I lost a little hope after removing the drip tray cover and the front panel thinking that the whole frame here was rusted through, but once I started vacuuming it out the "rust" came off easily and smelled like absolute hell, I'm pretty sure this was layers of milk and coffee that have dried over time. The last pic shows how well it came off with only gentle persuasion, there is hope.

That is where it stands now, this will be a slow moving project as my first goal is to get it working, then I will dismantle the whole and thing and sandblast the frame and soak everything in de-scaler and replace all of the seals and gaskets, still need to test the heating element as well. Luckily the rear body panel looks to have suffered minimal damage and is in good shape, a little polish and it will look great.

I'll enjoy this project as it can be done in my basement, comfortably standing or sitting on a stool at the workbench. No climbing, crawling, or crowding around a car in a small basement garage and no dust and extended cleanup like the wood working stuff. Can't do much woodwork in the basement as the dust may not work well with a gas powered furnace and water heater down there, don't want to risk anything. This is nice and compact and only issue will be any water leakage which can just be shut off and cleaned up enough to dry.

Plan is to try and hunt down the body panels, mainly the drip tray, and try to hammer the current ones straight. Make new legs out of some oak I have and just make it function. Want to replace the current steam pressure gauge with a dual pressure one so I can see the pump pressure while making espresso