You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

project: pissedoffsol

- Thread starter posol

- Start date

- Replies 1K

- Views 92K

We may earn a small commission from affiliate links and paid advertisements. Terms

rudeludenotmeanthough

Senior Member

this has turned into the lost post. Back from the Dead!!!!!!!!

Day 8

Well, im fucking freezing. It's like 34 degrees out right now up here in good ol' CT. I called it a night early on. I can't WAIT to take a shower and warm up a little bit.

After 8 hours in the garage, and a couple from last night that I didn't post about, I got 4 things done. 3-bar map is wired, GE oil filter sandwhich adapter is in place, oil pressure gauge sending unit is connected, and downpipe is on. Now, that doesn't mean that that's all I TRIED to do today...

YESTERDAY:

Started out with some cleaning. got a couple bags of trash, and tore/flattened boxes for about an hour. lol fastet garage in the world no longer exists :/

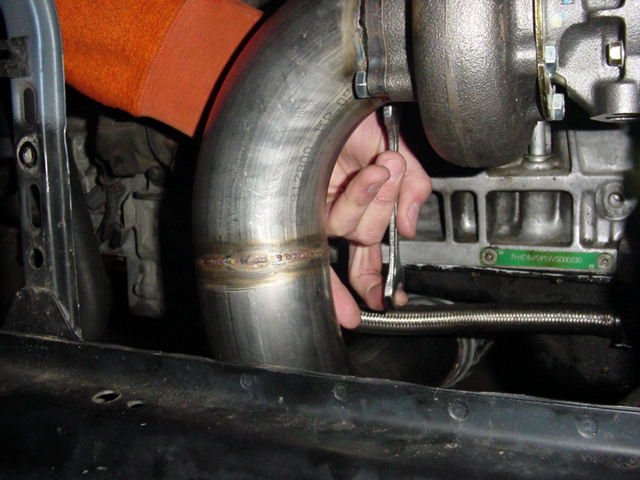

The downpipe was a BITCH. the bolts that hold it onto the turbo simply didn't fit due to the bends in the pipe. it was IMPOSSIBLE to use the washers. they are simply just too big. After 3 hours of Bill and I fucking with it yesterday, we finially got it on. That was all we did yesterday.... other than put a bungee cord to temp. hold the IC in place. Anyway, the DP is set up like the TB is- 2 bolts, and 2 double threaded studs for 2 nuts. The only way to work it was to use the 2 studs on the bottom, instead of a "2 and 8" criss cross of the bolts vs studs. The dimples in the DP are simply not dimpled enough I guess... every turn to tighten, it scraped at the DP.

here's some shots of it...

Today, bill was out with his girl, so I was all alone. I figured I'd tackle some easy stuff.... 1 person jobbers and so forth.

started with the sandwich plate... went on pretty easy. filter bolted right up to it. i didn't get any pics of the underside... maybe tomorrow if i remember.

Here's the pressure gauge sending unit all connected up and half wired.

I decided to throw my avcr and vafc into the glvoe box. they don't fit well, but hey, they will be out of the way. I cut a notch (and did a SHIT job of doing this) to fit the connectors through the back of the glove box. i broke 3 double-sided razor blades in the process.

I taped them in for now with some doublesided tape... they fit snug, so they aren't flopping around as it is, and the tape will hold. I'm not sure if im going to change this or not eventually, but for now, it will do.

they are out of the way, and easy to access if needed. the only thing that might be a biitch is when they are being used, which honestly, after im tuned, they probably won't even be touched. so, out of the way.

here's the box back in the car...

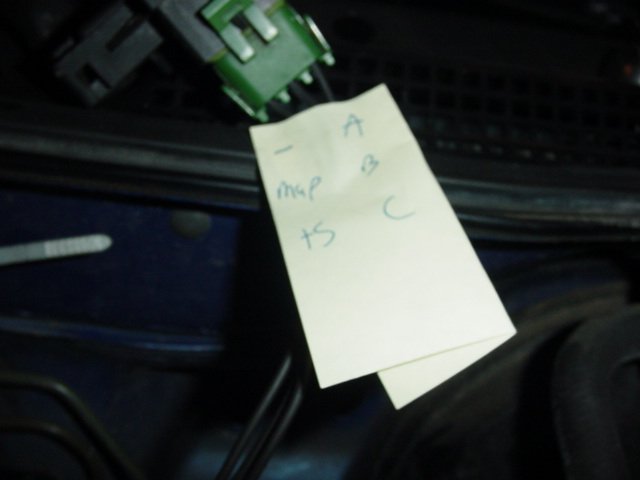

Well, here's the 3-bar install. The previous owner also had one, so it saved me a lot of BS work. I checked his connections, and they were soldered. I re-taped everything though. Instead of re-soldering my harness from the 3-bar into the oem harness, I used his connections, and simply cut/pasted my wiring onto his.

here's the pin out

More coming in a sec.... gotta make a new post (too many damn pics lol)

Well, im fucking freezing. It's like 34 degrees out right now up here in good ol' CT. I called it a night early on. I can't WAIT to take a shower and warm up a little bit.

After 8 hours in the garage, and a couple from last night that I didn't post about, I got 4 things done. 3-bar map is wired, GE oil filter sandwhich adapter is in place, oil pressure gauge sending unit is connected, and downpipe is on. Now, that doesn't mean that that's all I TRIED to do today...

YESTERDAY:

Started out with some cleaning. got a couple bags of trash, and tore/flattened boxes for about an hour. lol fastet garage in the world no longer exists :/

The downpipe was a BITCH. the bolts that hold it onto the turbo simply didn't fit due to the bends in the pipe. it was IMPOSSIBLE to use the washers. they are simply just too big. After 3 hours of Bill and I fucking with it yesterday, we finially got it on. That was all we did yesterday.... other than put a bungee cord to temp. hold the IC in place. Anyway, the DP is set up like the TB is- 2 bolts, and 2 double threaded studs for 2 nuts. The only way to work it was to use the 2 studs on the bottom, instead of a "2 and 8" criss cross of the bolts vs studs. The dimples in the DP are simply not dimpled enough I guess... every turn to tighten, it scraped at the DP.

here's some shots of it...

Today, bill was out with his girl, so I was all alone. I figured I'd tackle some easy stuff.... 1 person jobbers and so forth.

started with the sandwich plate... went on pretty easy. filter bolted right up to it. i didn't get any pics of the underside... maybe tomorrow if i remember.

Here's the pressure gauge sending unit all connected up and half wired.

I decided to throw my avcr and vafc into the glvoe box. they don't fit well, but hey, they will be out of the way. I cut a notch (and did a SHIT job of doing this) to fit the connectors through the back of the glove box. i broke 3 double-sided razor blades in the process.

I taped them in for now with some doublesided tape... they fit snug, so they aren't flopping around as it is, and the tape will hold. I'm not sure if im going to change this or not eventually, but for now, it will do.

they are out of the way, and easy to access if needed. the only thing that might be a biitch is when they are being used, which honestly, after im tuned, they probably won't even be touched. so, out of the way.

here's the box back in the car...

Well, here's the 3-bar install. The previous owner also had one, so it saved me a lot of BS work. I checked his connections, and they were soldered. I re-taped everything though. Instead of re-soldering my harness from the 3-bar into the oem harness, I used his connections, and simply cut/pasted my wiring onto his.

here's the pin out

More coming in a sec.... gotta make a new post (too many damn pics lol)

Attachments

Last edited by a moderator:

So, with that out of the way, i figured i'd mess with the charge pipes a little.

They certainly don't line up as good as i had hoped they would...

Top view of the mani/turbo/dp:

turbo -> into FMIC coupling... its kinda crooked. I don't know... I need to play with it some more i think

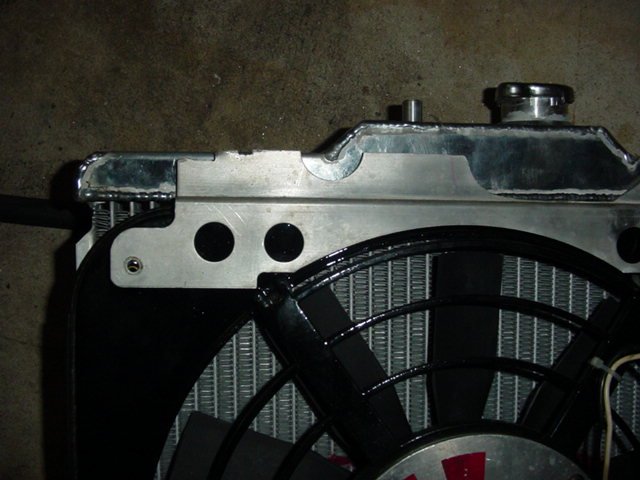

And now, part 4 that pissed me off. Either I'm an idiot, or there is no fucking way to mount a FAL fan onto a PWR radiator.

Where the bolt holes are, there are simply no taps on the rad. for it to screw into. it almost looks like the fan is on the wrong side........

ohh wait, yeah, its def on the wrong side. lol

the pics i took are backwards, and i realized that when i took them, but on the other side, there are still no mounting holes that line up with anything on the fal fan. so who the hell knows who im going to do with that either.

In lighter news, the cap has a funny dude on it

On the inside, I got the p28 out, and the hondata p28 in with the control unit. I didn't mount it back up yet because i have about 7 different' things i still need to wire up and that's where its going to take place (gauges, timer, etc)

I took out the center vents- as i took out the a/c, and i pretty much always have my heat control on def/floor combo, and I think im going to put 2 gauges in there.

The skunk2 shifter/knob that i never got a pic of yet from a couple days back...

The pic sucks, but its the GE vacuum port/manifold thingge they sell. Again, this one came to me slightly opened (see a few days back about the GE rail that I also got from MM). It states CLEARLY in the parts list that there are supposed to be 2 supplied mounting self-tapping screws. Guess what? MM STOLE THEM OUT OF THE BOX before they shipped it out to me. This is the 2nd part they did that to me on.

I'm severely pissed off at this. A FUCKING BOLT! I mean, Christ, they are a shop! there is no fucking need to "borrow" one out of a customer's part.

I'm going to write to golden eagle as well, explain the situation, and hopefully, they will drop MM as an authorized dealer. Cuz that's just wrong.

They certainly don't line up as good as i had hoped they would...

Top view of the mani/turbo/dp:

turbo -> into FMIC coupling... its kinda crooked. I don't know... I need to play with it some more i think

And now, part 4 that pissed me off. Either I'm an idiot, or there is no fucking way to mount a FAL fan onto a PWR radiator.

Where the bolt holes are, there are simply no taps on the rad. for it to screw into. it almost looks like the fan is on the wrong side........

ohh wait, yeah, its def on the wrong side. lol

the pics i took are backwards, and i realized that when i took them, but on the other side, there are still no mounting holes that line up with anything on the fal fan. so who the hell knows who im going to do with that either.

In lighter news, the cap has a funny dude on it

On the inside, I got the p28 out, and the hondata p28 in with the control unit. I didn't mount it back up yet because i have about 7 different' things i still need to wire up and that's where its going to take place (gauges, timer, etc)

I took out the center vents- as i took out the a/c, and i pretty much always have my heat control on def/floor combo, and I think im going to put 2 gauges in there.

The skunk2 shifter/knob that i never got a pic of yet from a couple days back...

The pic sucks, but its the GE vacuum port/manifold thingge they sell. Again, this one came to me slightly opened (see a few days back about the GE rail that I also got from MM). It states CLEARLY in the parts list that there are supposed to be 2 supplied mounting self-tapping screws. Guess what? MM STOLE THEM OUT OF THE BOX before they shipped it out to me. This is the 2nd part they did that to me on.

I'm severely pissed off at this. A FUCKING BOLT! I mean, Christ, they are a shop! there is no fucking need to "borrow" one out of a customer's part.

I'm going to write to golden eagle as well, explain the situation, and hopefully, they will drop MM as an authorized dealer. Cuz that's just wrong.

Last edited by a moderator:

once again for the people who think they can do engine swaps or turbo installs in a day or two...

chances are parts will either be missing or not fit right shit happens

this is not a flame to you B since you don't think its a day or even a week job

Im just sick of hearing from people how they can do a turbo install or engine swap a 1 weekend

shit does and will go wrong

hey whats the addy to MM? I want to check the site out so I can burn a image into my head of what place to not buy from

Jeff

chances are parts will either be missing or not fit right shit happens

this is not a flame to you B since you don't think its a day or even a week job

Im just sick of hearing from people how they can do a turbo install or engine swap a 1 weekend

shit does and will go wrong

hey whats the addy to MM? I want to check the site out so I can burn a image into my head of what place to not buy from

Jeff

Originally posted by jeffie7@Oct 19 2003, 09:49 PM

once again for the people who think they can do engine swaps or turbo installs in a day or two...

chances are parts will either be missing or not fit right shit happens

this is not a flame to you B since you don't think its a day or even a week job

Im just sick of hearing from people how they can do a turbo install or engine swap a 1 weekend

shit does and will go wrong

hey whats the addy to MM? I want to check the site out so I can burn a image into my head of what place to not buy from

Jeff

oh so true.

E's ITR swap took 2 weeks.

im probably going to be 3- maybe 4.

motormatrix.com is the site. stay away.

Shit my z6 swap into my Civic ended up taking 2 weeks. It would have been quicker but things like getting a blown engine, then the starter took a shit, the junkyard being a day late in delivering the engine, school, and easter took time from getting it done quickly.

B things will work out alright, if you ever need another hand wrenching let me know.

B things will work out alright, if you ever need another hand wrenching let me know.

getting everything installed properly with a turbo setup is not an easy task. the wiring and tuning will be the most difficult...and that is yet to come. as far as the piping, i'd find someone in bristol who can bend pipes and have everything done by them using the dimensions you designate.

as far as an all motor swap, i've done one swap in 5 hours...and seen several COMPLETE motor swaps done in less than 4 hours. it takes power tools, all of the right parts, and lots of experience.

good luck brian, can't wait to see the car when its finished...it should absolutely rip.

as far as an all motor swap, i've done one swap in 5 hours...and seen several COMPLETE motor swaps done in less than 4 hours. it takes power tools, all of the right parts, and lots of experience.

good luck brian, can't wait to see the car when its finished...it should absolutely rip.

ScrapinSi

Senior Member

Originally posted by jeffie7@Oct 19 2003, 08:49 PM

once again for the people who think they can do engine swaps or turbo installs in a day or two...

chances are parts will either be missing or not fit right shit happens

this is not a flame to you B since you don't think its a day or even a week job

Im just sick of hearing from people how they can do a turbo install or engine swap a 1 weekend

shit does and will go wrong

hey whats the addy to MM? I want to check the site out so I can burn a image into my head of what place to not buy from

Jeff

hehehehe.... Mine will be done tomorrow FINALLY... I've been workin on my install since July...

#1. Incorrect water temp sending unit for CyberDyne Gauge

#2. Another incorrect sending unit

#3. Incorrect turbo timer wiring and keyless entry wouldn't work

#4. Welded BOV flange on and now strut bar won't go back on b/c of vaccuum fitting

#5. Intercooler endtanks

#6. Intercooler piping didnt fit right

#7. Intercooler piping didnt fit right

#8. Downpipe was a bitch to make

#9. AEM FPR apparently has a ripped diaphragm and causes 90psi fuel pressure

#10. RC Injectors have OBD1 Clips I need obd2 clips

#11. Wired my obd Xover harness wrong... THREE TIMES...

#12. Chipped my ECU with a blank program and couldn't get it to erase the chip correctly

#13. Wastegate dumptube was a BITCH to make work right

And there are more that i'm not even bothering to mention...

snowboarderguy44

Member

hey B i saw a lil trick setup on an S2K. He had the V-AFC, and the AVCR installed on the sun visor. It wuz a sick setup, he ran the wiring behind the A-pillar and behind the dash. Plus it wud save ur glovebox for other essentials (maps, condoms, the gun to shoot would-be car jackers

ScrapinSi

Senior Member

How often are you going to need your HVAC controls? move those to the glovebox, and mount the AFC in the a/c vents, and the avc-r where the HVAC controls go....

Or mount the AFC where the cupholder door is, and mount the AVC-R inside of the cupholders... so 1 look its an AFC, another its an AVC-R...

Or mount the AFC where the cupholder door is, and mount the AVC-R inside of the cupholders... so 1 look its an AFC, another its an AVC-R...

Similar threads

- Replies

- 43

- Views

- 5K