Loco Honkey

Banned

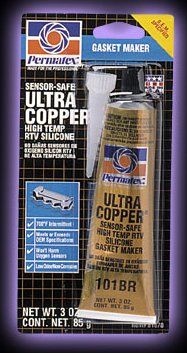

OK Brian... breathe... OK, are you listening to me? It's going to be OK... the reason that one port on that gasket doesn't have any carbon on it was because it was sealed properly on just that one cylinder. That was the cylinder I tested spark on... it's OK... just get that damn thing shaved and you'll be fine.