You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DA9 GSR SWAP

- Thread starter DA9don

- Start date

- Replies 42

- Views 26K

We may earn a small commission from affiliate links and paid advertisements. Terms

If that is the case, check for a plug that's not plugged into anything under the Dash near the kick panel. It may be in the kick panel. You can take a paper clip and bend it into a u so you can jump both sides of the plug. Then turn key to on position and read the flashing lights given to you. You can then use those numbers to tell you what is your check engine light. Long Flash equals 10 and short flash equals 1. Add them together to tell you the code.

DA9don

Member

So today I went ahead and replaced the map sensor with the one I got from the junkyard and the car ran a lot better than before. I decided to check the Check Engine Light and I have 4 codes.

21 - VTEC Solenoid

22- VTEC Oil Pressure

23 - Knock Sensor

7 - Throttle Angle

When I first did the swap, I ran the car with out both the vtec solenoid and pressure switch hooked up. As far as the knock sensor goes, I found it to be loosely connected (will be swapping the connector). I will be repositioning my throttle angle.

Heres a pic of the cockpit. I was able to get my horn working by using a 90 Integra RS clock spring (idk what the part is actually called)

#13 is what I replaced.

21 - VTEC Solenoid

22- VTEC Oil Pressure

23 - Knock Sensor

7 - Throttle Angle

When I first did the swap, I ran the car with out both the vtec solenoid and pressure switch hooked up. As far as the knock sensor goes, I found it to be loosely connected (will be swapping the connector). I will be repositioning my throttle angle.

Heres a pic of the cockpit. I was able to get my horn working by using a 90 Integra RS clock spring (idk what the part is actually called)

#13 is what I replaced.

clock spring is the correct term!

should be fairly easy. i had a mugen wheel in my 92 civic. abou the same setup.

DA9don

Member

Just to clarify, you bought number 13 in the diagram and put it in your aftermarket steering wheel. And the horn works now?

No did not buy it brand new. It would be rare to buy it brand new. I actually went to the junkyard came across a BASE MODEL Integra RS.

DA9don

Member

So I am trying to fix my TPS but for some reason, I am not getting .5 volts. I checked for continuity on my engine harness and cabin harness. I checked to see if I'm getting any voltage out of the P61 ECU and I am not receiving any type of voltage or reading. I back probed connector D pin 20 for any voltage with the car on and I get no reading. idk what to do, fixed my other codes but I still get a code 7 and I'm trying calibrate my TPS.

PLEASE HELP!

PLEASE HELP!

Your TPS has screws or rivets attaching it to the throttle body?

Are you tapping into the red wire?

Are you sure you are getting penetration through the insulation?

If you were getting a code for TPS and it was riveted to the throttle body, you then detach the TPS rivets and tried to calibrate it with no success , then I figure the TPS is bad.

Are you tapping into the red wire?

Are you sure you are getting penetration through the insulation?

If you were getting a code for TPS and it was riveted to the throttle body, you then detach the TPS rivets and tried to calibrate it with no success , then I figure the TPS is bad.

DA9don

Member

Your TPS has screws or rivets attaching it to the throttle body?

Are you tapping into the red wire?

Are you sure you are getting penetration through the insulation?

If you were getting a code for TPS and it was riveted to the throttle body, you then detach the TPS rivets and tried to calibrate it with no success , then I figure the TPS is bad.

I removed my old TPS from the old LS motor and swapped it over to my SKUNK2 70mm Throttle body. After removing the rivets, I replaced it with screws. I did not want to remove the original TPS from the original B17A1 throttle body just because if I wanted to go back to stock I wouldn't have to mess with it. No I did not calibrate it but I was trying to calibrate it earlier today and was having trouble. Was not getting any type of voltage but I was getting continuity for my ground. What I will try to do is probe power to my TPS and see if it works before swapping. I checked all cabin harness and engine harness and was able to get continuity using a volt meter. When I back probed connector D pin 20 on my P61 eco, I was not getting any readings. Makes me wonder if my eco has a bad connection or I have a bad female pin connector on connector D.

DA9don

Member

Okay guys, small update. I was not able to get my TPS calibrated. I am not getting any continuity in my Cabin Harness when checking the TPS wires. Also I did realize that LS engines did not come with KNOCK sensors which is why I have a code 23 on my B17. Awhile back, I have purchased a RYWIRE OBD1 Budget Harness for a 92-93 Integra GSR. I bought this harness because I thought I was getting a FULL DB2 GSR Cabin/Engine Harness but dude ended up flaking and saving it for himself. I was stuck with the harness until I emailed RYWIRE and asked if I can change the chassis harness to my LS Cabin harness. RYWIRE helped me out and I went ahead and ordered the chassis harness. Now ill be able to use my RYWIRE harness which has all the connectors that I need and I won't have to worry about any breaks in the wires. It may seem I am just going around the problem but it was my original plan in the first place. I also went ahead and purchased a OBD1 ECU Female Connector Housing so that I can connect/disconnect from the ECU connector.

If you guys are wondering about how I got my horn working, here are some pics. I didn't take to many but it gets a feel on how it works.

TOP Clock Spring LS, GS, GSR: Horn and Cruise Control

BOTTOM Clock Spring RS: Horn Only (Notice the copper spring sticking out? That will make contact with the aftermarket hub.)

Removed the old clock spring and de-pinned and utilized the harness only with the one connector which is the horn.

I went ahead and put a Female Crimp Connector after stripping it. I did cut the bottom copper piece so that I can utilize the female crimp connector. This just makes it easier to install and it doesn't get in the way .

Using the original harness just makes it simple and you can put it back in the stock position.

Didn't take a lot of pics or final out come with out the steering wheel. Was just excited to get everything back on with a working horn. Hope this can help you guys IF you guys wanted a working horn.

If you guys are wondering about how I got my horn working, here are some pics. I didn't take to many but it gets a feel on how it works.

TOP Clock Spring LS, GS, GSR: Horn and Cruise Control

BOTTOM Clock Spring RS: Horn Only (Notice the copper spring sticking out? That will make contact with the aftermarket hub.)

Removed the old clock spring and de-pinned and utilized the harness only with the one connector which is the horn.

I went ahead and put a Female Crimp Connector after stripping it. I did cut the bottom copper piece so that I can utilize the female crimp connector. This just makes it easier to install and it doesn't get in the way .

Using the original harness just makes it simple and you can put it back in the stock position.

Didn't take a lot of pics or final out come with out the steering wheel. Was just excited to get everything back on with a working horn. Hope this can help you guys IF you guys wanted a working horn.

nice! that feels like what i had to do with my EH  to get the mugen horn to work.

to get the mugen horn to work.

DA9don

Member

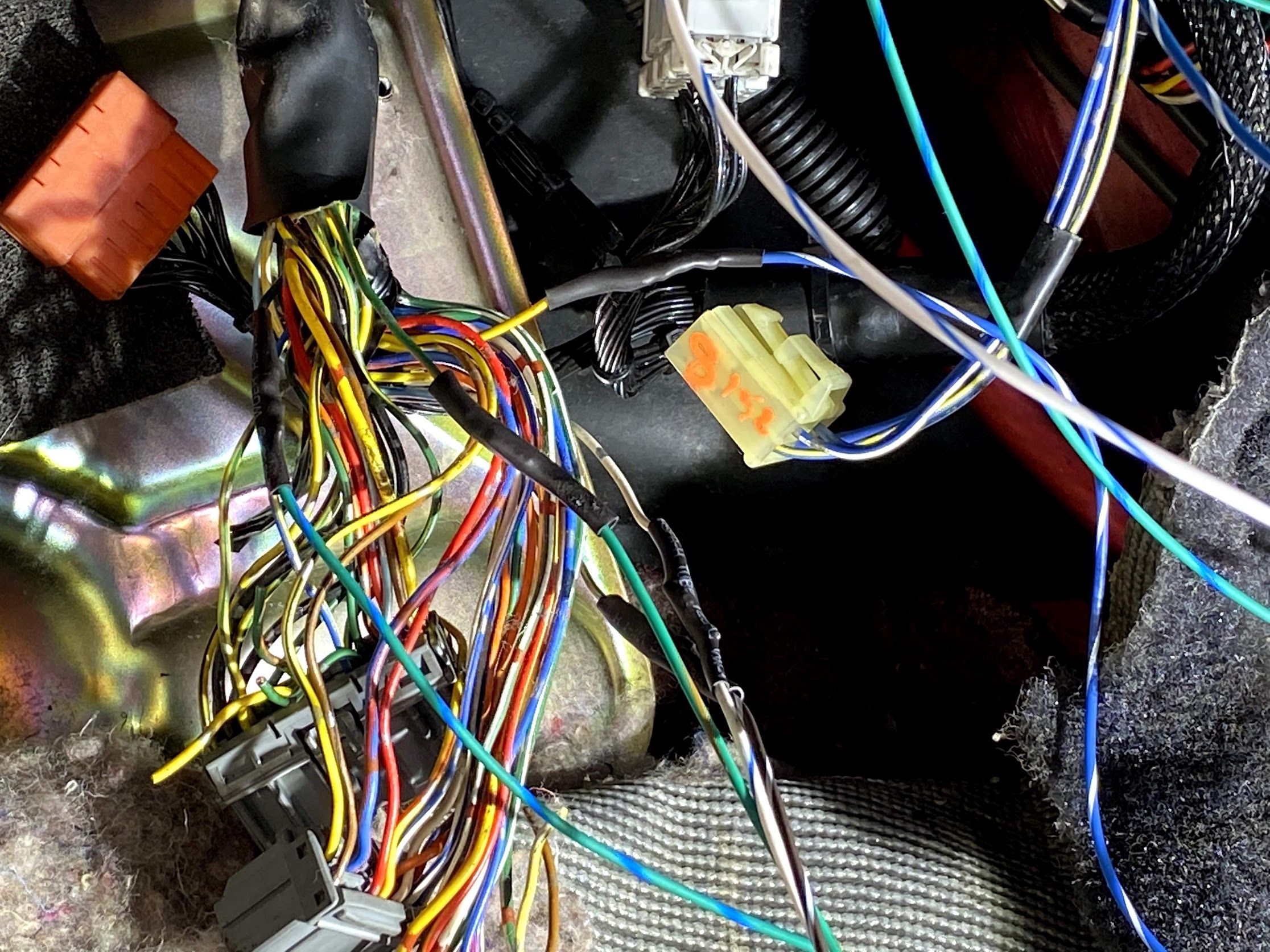

So before I put the engine in, I had the RYWIRE harness installed on the engine itself.

This is the harness that needs to be changed out in order for the harness to work with the chassis. The harness that I bought will look similar to this. It will have those same loose strands of wires that have to wire and connect myself. I did not want to cut and splice wires so instead I bought the female adapter from HA Motorsports. HA Motorsports - Honda / Acura Engine Management Solutions

This is the harness that needs to be changed out in order for the harness to work with the chassis. The harness that I bought will look similar to this. It will have those same loose strands of wires that have to wire and connect myself. I did not want to cut and splice wires so instead I bought the female adapter from HA Motorsports. HA Motorsports - Honda / Acura Engine Management Solutions

DA9don

Member

Whats up guys. No new updates other than receiving my rywire chassis harness adapter. The adapter harness that I bought was not what I was expecting, didn't read the description all the way so that was my fault. I will still keep it for now just in case if I need it. I went ahead and pulled the the glove box, a/c, and blower motor out to run the rywire harness. I am not doing a full tuck (later on I will be simplifying my cabin harness in the future, just too busy), just wanted a piece of mind of a new engine harness. Didn't take pics of the full process but went ahead and installed. I was able to get everything wired correctly, I still have a check engine light but come to find out, I have bad ECU. I already removed my throttle body and it calibrated/adjusted my TPS using my friends Honda Civic. It sucks but I will be looking for another ECU or have my P61 get inspected/repaired.

DA9don

Member

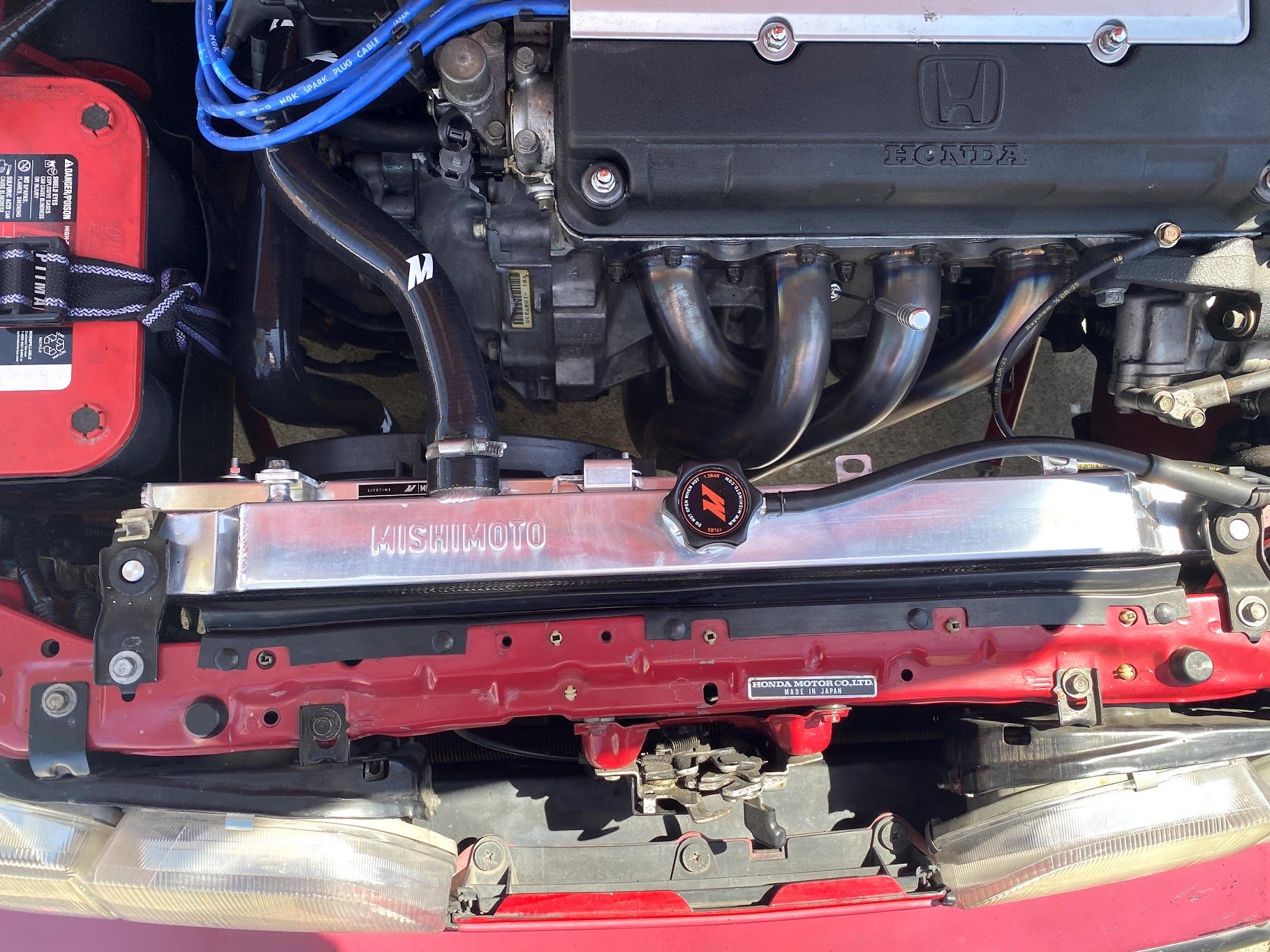

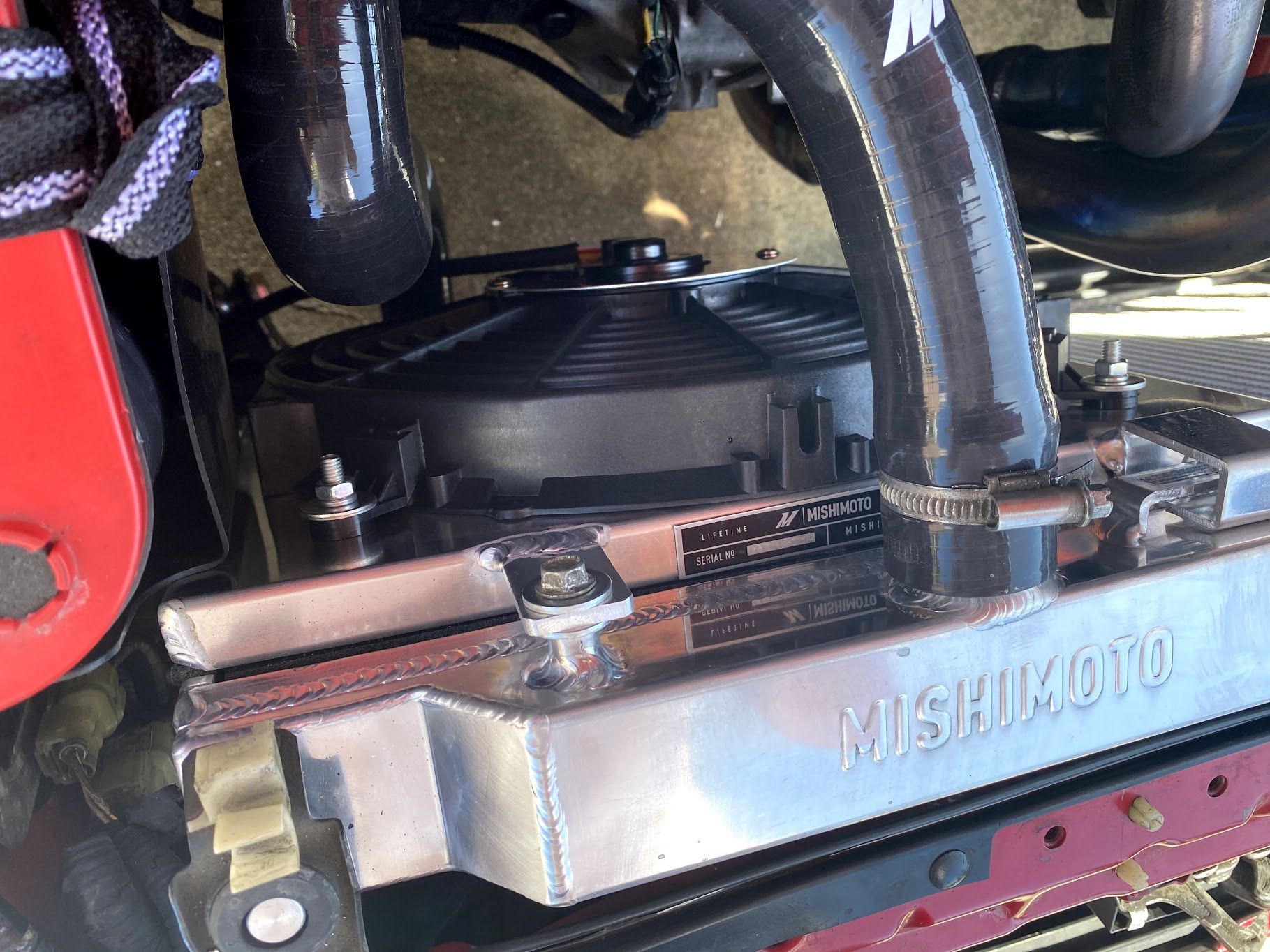

Whats up guys, I was able to get check engine light to go away. I had 2 problems with the TPS. My TPS was not in correctly on the throttle and was able to get the check engine light to go away. While test driving, the check engine light came back on. Found a bad connection on the ECU itself and fixed the soldering point. ECU soldering was cracked, idk how it happened but just soldered and slapped it back into the car. Also got my Mishimoto radiator, hoses, and slim fan. Found my old upper radiator to be leaking and my radiator started to leak coolant. started to see puddles of coolant after each drive these past few weeks. Last thing I need to do for the engine is make sure my timing is all set because I did find my idle to be very low.

DA9don

Member

glad you got the cels to go away. Seems like you're running at operating Temps in the photo. She seems to be idling pretty high. Is that something you did on purpose? Maybe it runs smoother?

I had the my foot on the pedal when I took a pic. I did not have a timing light nor I didn't want to adjust my idle screw on the skunk2 throttle body just yet. I went ahead I got timing done and made sure my idle was perfect after that.

Similar threads

- Replies

- 6

- Views

- 940

- Replies

- 9

- Views

- 7K